Overview

ORER's new chain electric hoist mainly has three styles: fixed, running, and low-headroom.

Product advantages

Meet the M5 working level and have a longer service life.

Pure copper motor, built-in friction clutch, built-in cooling air conditioner, efficient heat dissipation and safer.

Up to IP65 protection level, suitable for operation in harsh environments.

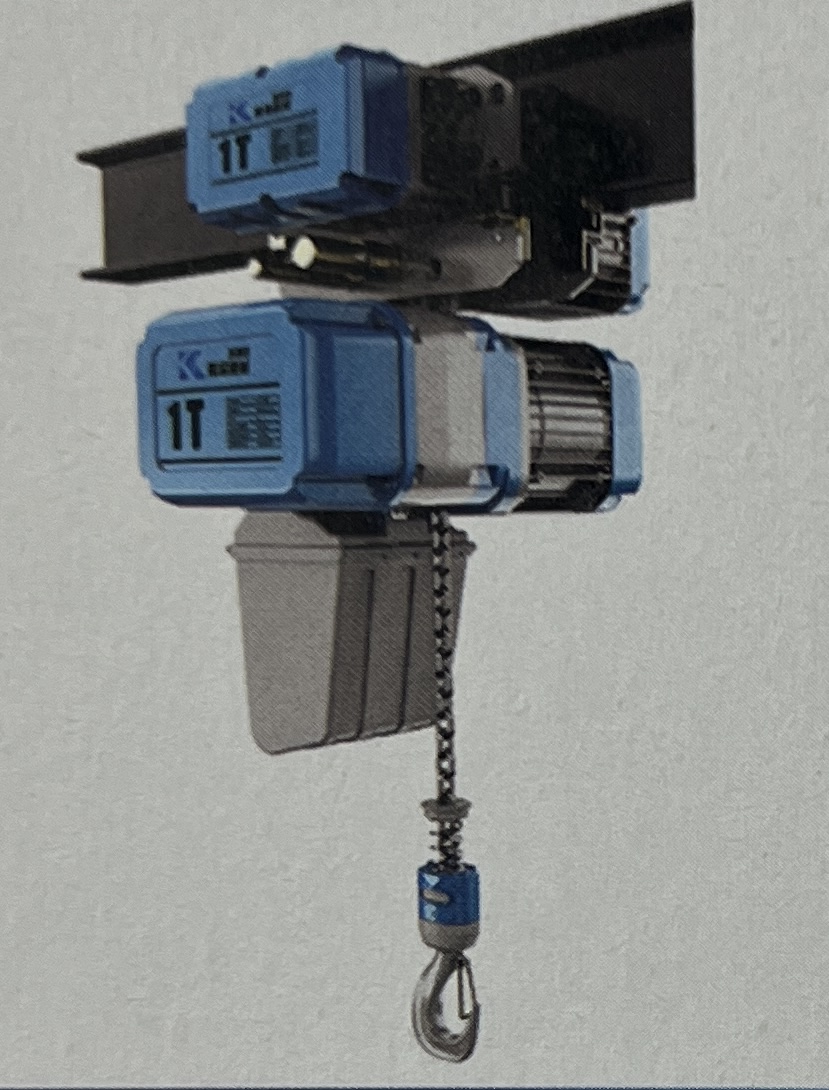

Fixed electric hoist

1. Rigidly fixed to the I-beam/steel structure, no lateral displacement, and extremely stable.

2. Adopting multi-layer winding wire rope technology, the anti-overlapping design extends the service life.

Case studies

1. Fixed-point lifting of engines in automobile manufacturing plants

2. Vertical disassembly and maintenance of reactors in chemical plants

3. Fixed-point loading and unloading of high-rise shelves in logistics centers

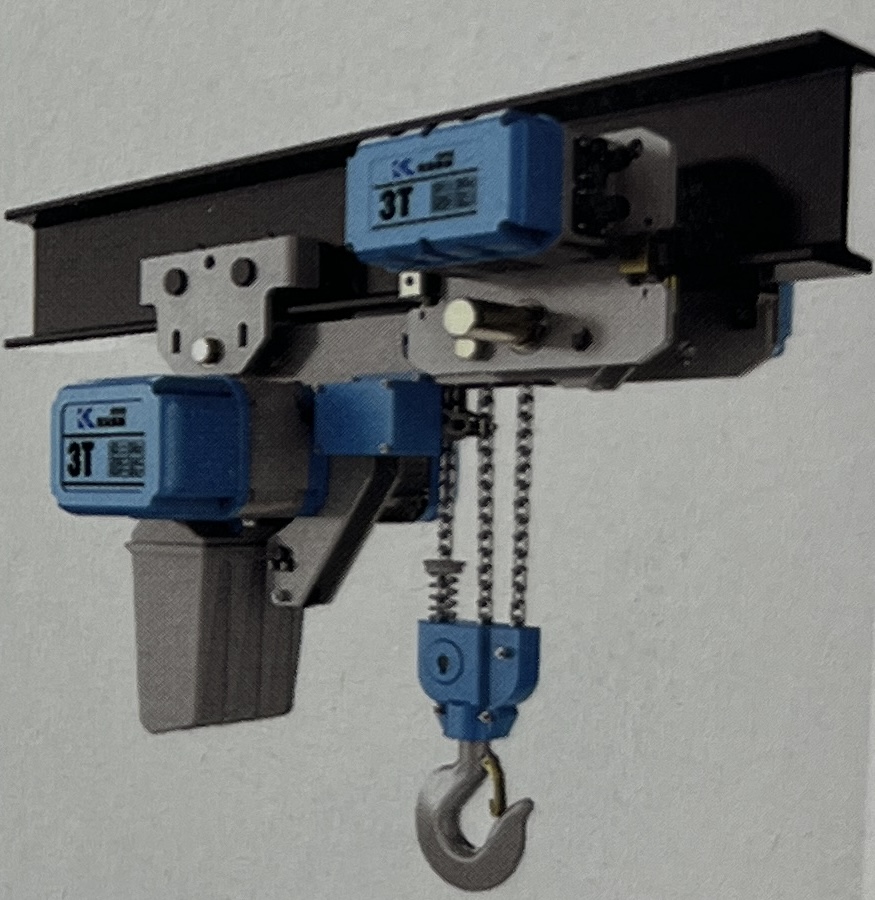

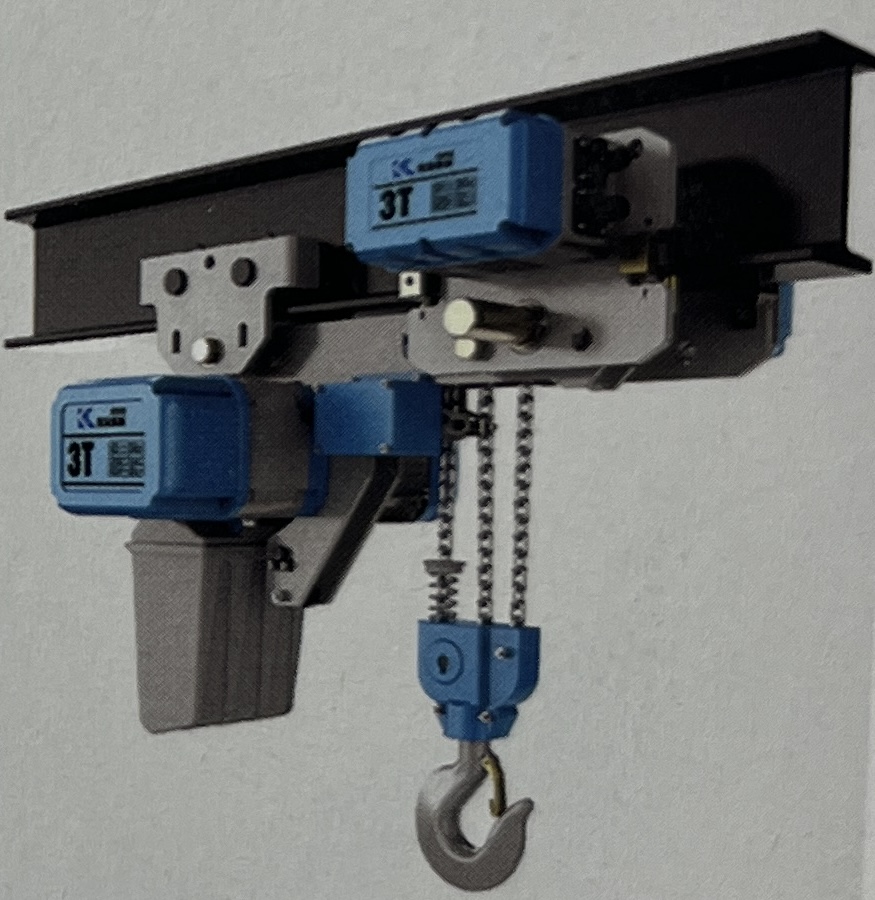

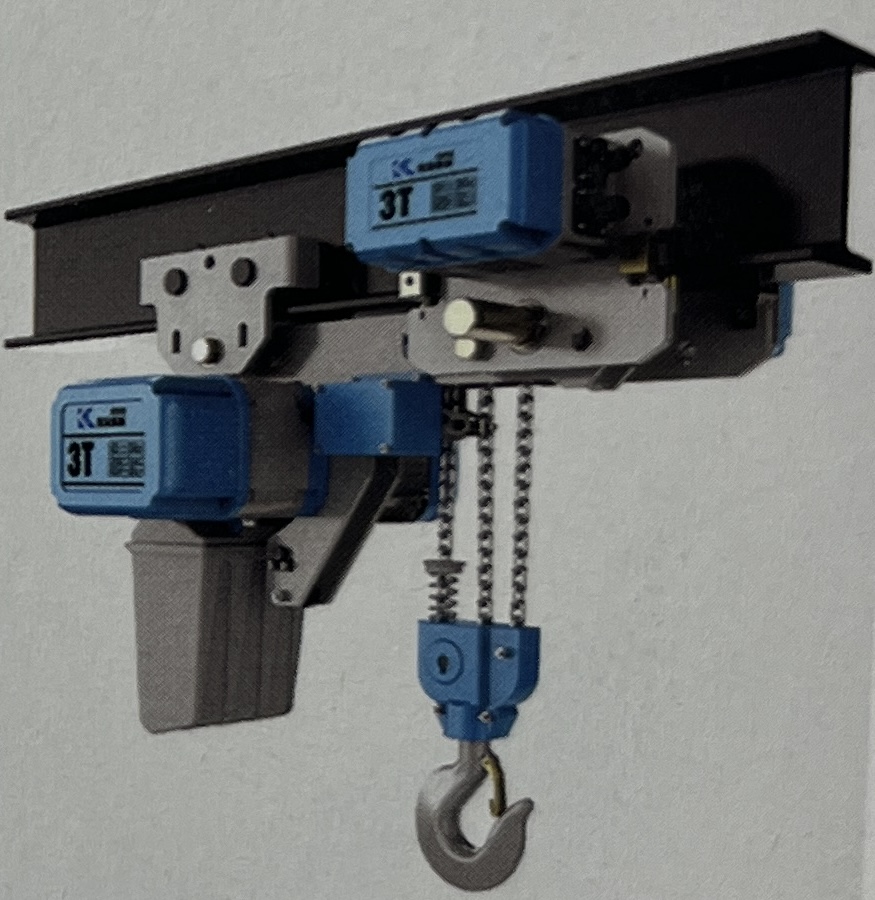

Running electric hoist

1. Equipped with an intelligent walking trolley, it supports horizontal movement of I-beam/double-beam tracks (adjustable speed 0-30m/min).

2. Wireless remote control + ground handle dual operation mode, adapting to complex human-machine collaboration scenarios.

1. Material transfer across regions in machining workshops.

2. Coordinated lifting of cabin sections in shipyards.

3. Flexible multi-station distribution on assembly lines.

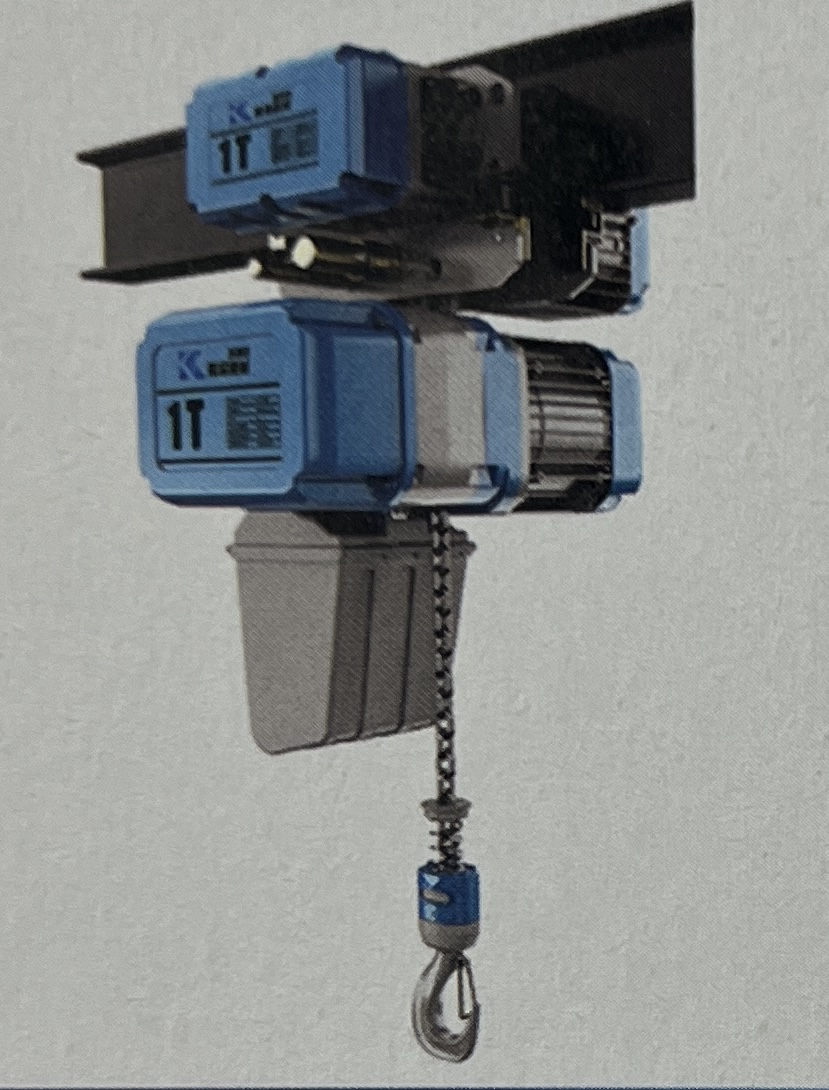

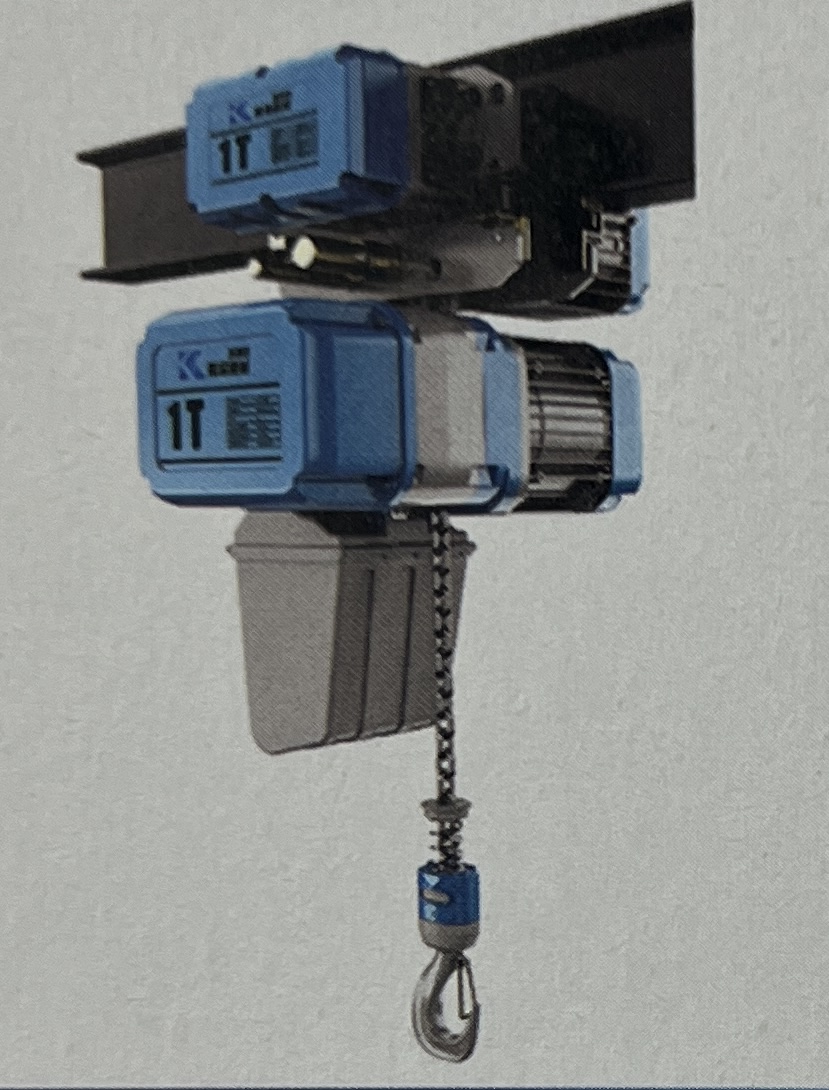

Low-headroom electric hoist

1. Unique flat drum structure, minimum headroom height is only 250mm (industry average 500mm).

2. Side-mounted motor design, width reduced by 40%, easily passing through narrow passages.

1. Installation of large equipment in underground parking lots.

2. Confined space operations in the renovation of old factories.

3. Aseptic lifting in clean workshops of food factories.

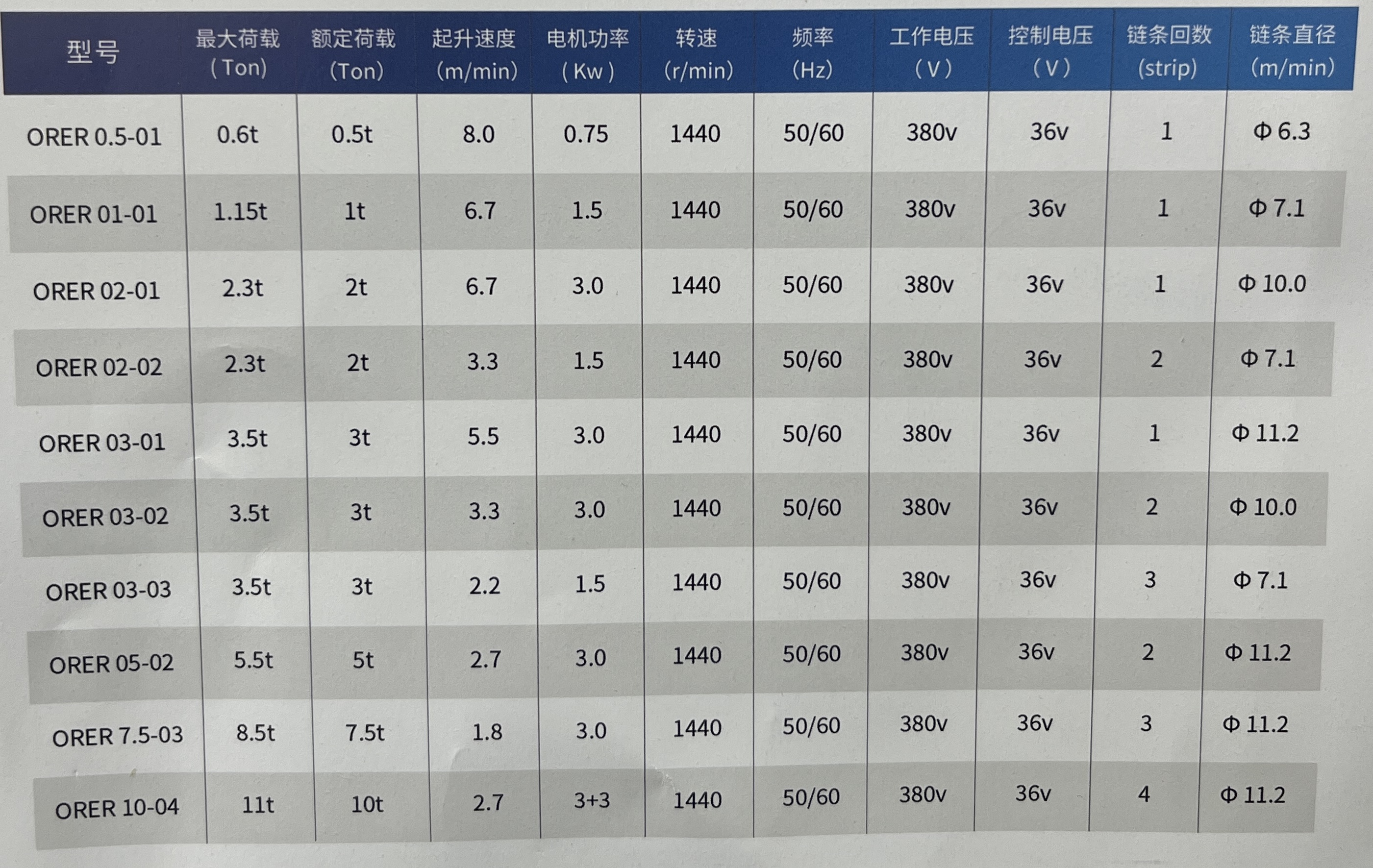

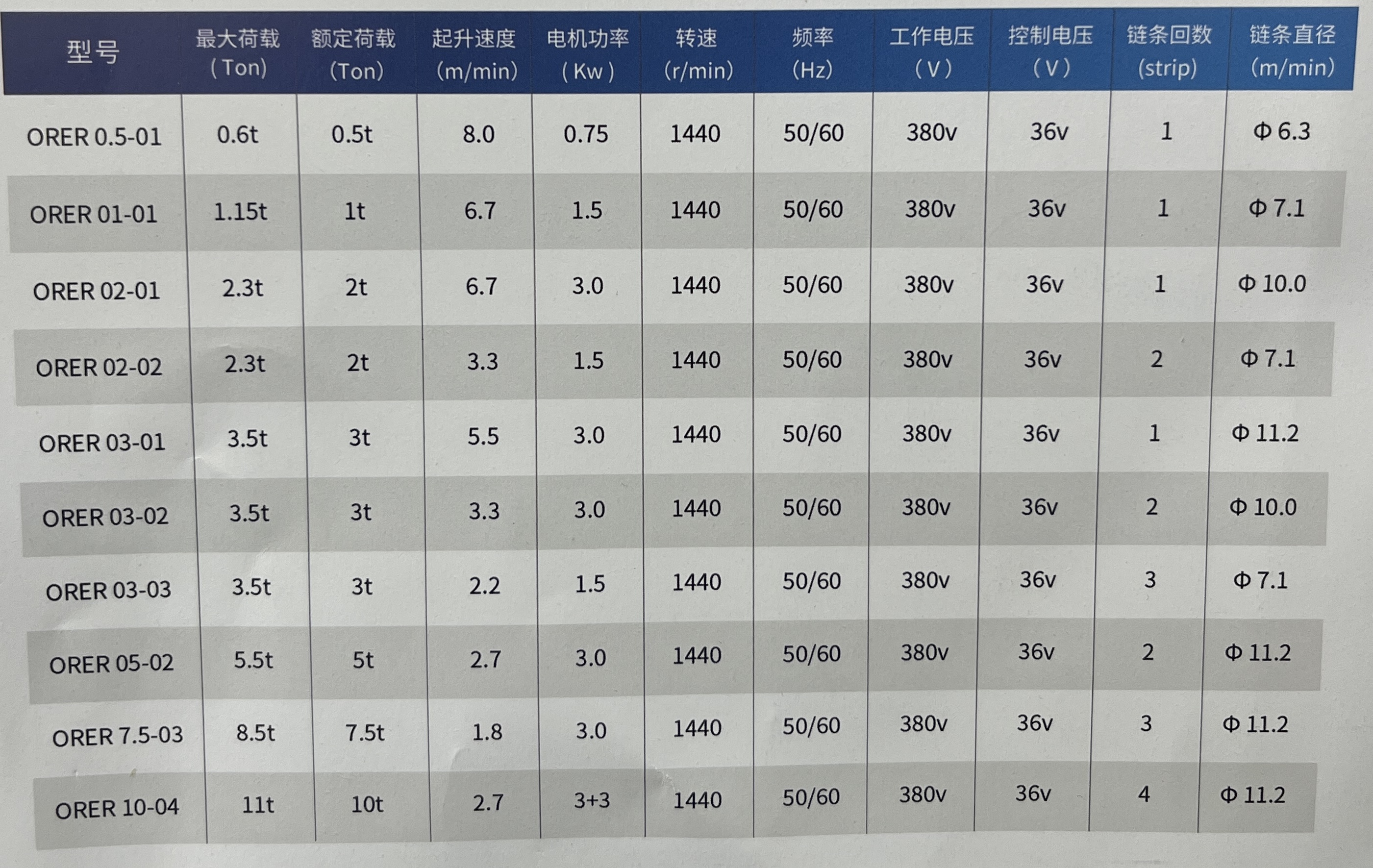

Technical parameters

Industry customized solutions

Automobile manufacturing: running type + AGV linkage to create a flexible and intelligent production line.

New energy battery: explosion-proof low-headroom hoist to meet the safety regulations of lithium battery workshops.

Aerospace: micron-level precision fixed hoist for precision component assembly.

Jinghe Crane Service and Certification

Global Standards: Passed ISO9001, ISO45001 system certification, in line with EN14492 European standard.

Quick response: Provide 3D working condition simulation selection, and issue customized solutions within 48 hours.

Lifetime escort: 10-year warranty commitment for key components, 200+ city service outlets coverage.