The electric chain hoist is an efficient and safe light and small lifting equipment, which is widely used in manufacturing, warehousing and logistics, construction sites, equipment maintenance and other fields. Its modular design, compact structure and diversified configuration can meet the needs of different scenarios.

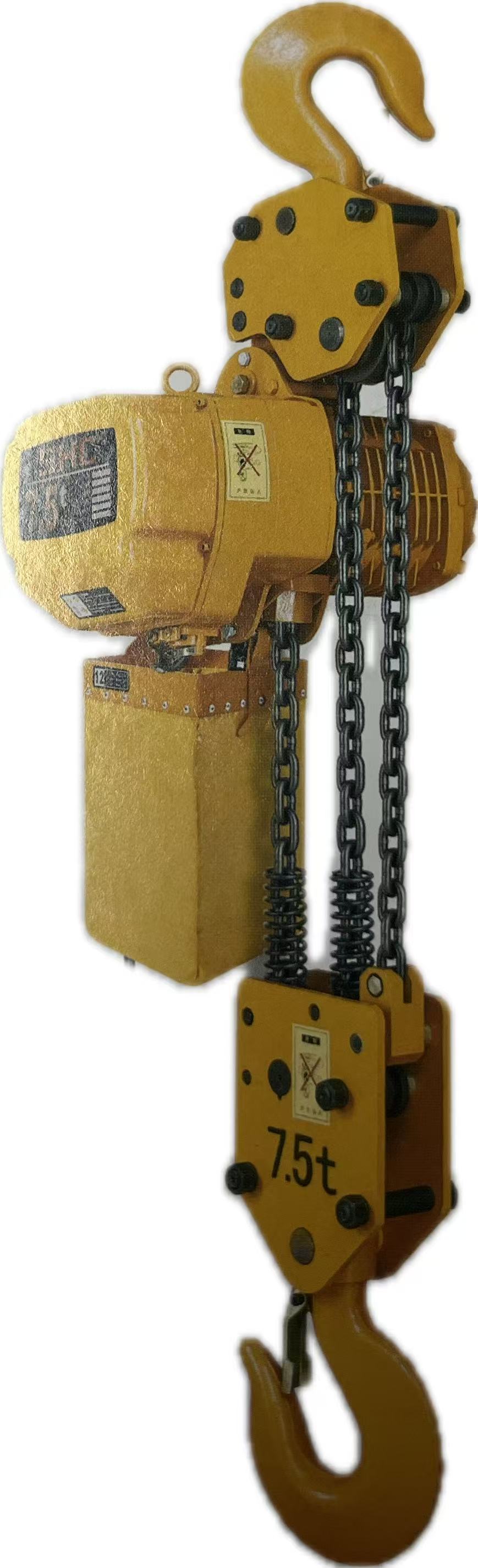

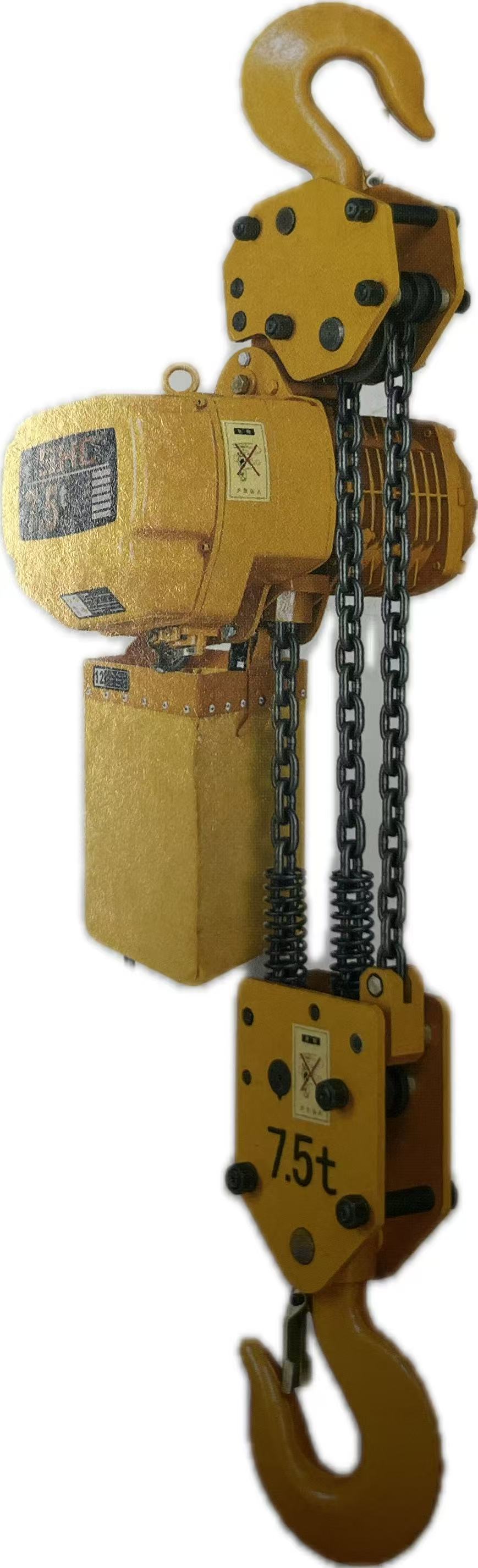

1. Hook-type electric chain hoist

Adopting the standard hook design, it can be directly hung on the I-beam, hanger or fixed fulcrum, which is easy to install and does not require a complex track system.

Rated load: 0.5~10 tons.

Lifting height: 3~30 meters (customizable).

Power supply: 380V/50Hz (standard) or customized voltage.

Strong flexibility, suitable for temporary or mobile operation scenarios.

Standard dual brake system, automatic locking when power is off.

Optional wireless remote control, operating radius of up to 100 meters.

Workshop equipment maintenance, small warehouse material handling, assembly line fixed-point lifting.

2. Hand-push operation electric chain hoist

The hoist is integrated in the hand-push trolley and can be manually pushed on the I-beam track to achieve horizontal movement.

Load range: 1~5 tons.

Track adaptability: I16~I25 I-beam.

Lifting speed: single speed/dual speed optional (0.8~8m/min).

Economical and practical, suitable for short-distance, low-frequency handling.

The trolley is equipped with wear-resistant nylon wheels, and the pushing resistance is reduced by 40%.

Mechanical limiter prevents derailment

Small workshop assembly lines, maintenance stations, laboratory equipment adjustment.

3. Electric-operated chain hoist

Equipped with an electric walking trolley, the hoist is driven by a motor to achieve fully automatic operation along the track.

Load range: 1~20 tons

Operation speed: 10~20m/min (variable frequency speed regulation optional).

Control mode: handle/remote control/PLC linkage control.

Improve work efficiency, suitable for long span and high frequency handling.

IP54 protection level, suitable for dust and humid environment.

Optional laser positioning system, accuracy ±5mm.

Large warehouse stacking, steel structure factory, automated production line.

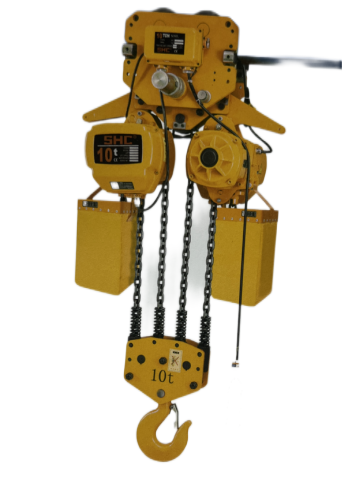

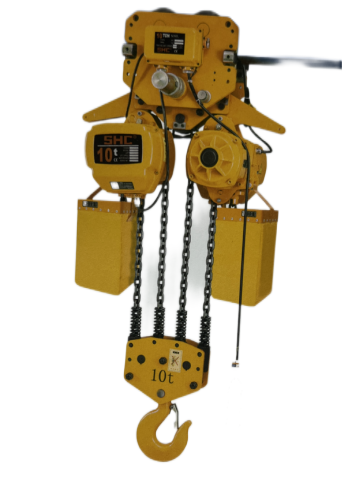

4. 10-ton running chain electric hoist

Optimize the structure for medium loads, strengthen the gearbox and sprocket set, and equip with overload protection sensor.

Hoisting motor: 4.5kW, F-class insulation.

Chain specifications: φ10mm alloy steel nickel-plated chain (anti-corrosion).

Safety devices: electronic weighing display, emergency stop button.

Machinery manufacturing workshop, building materials loading and unloading, medium-sized equipment installation.

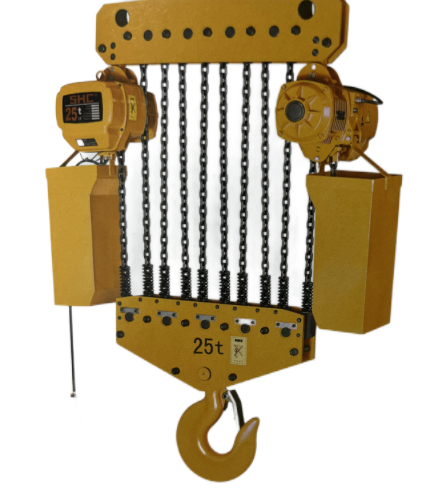

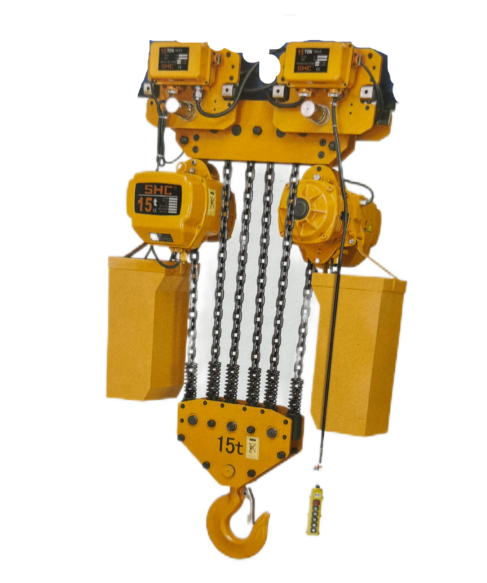

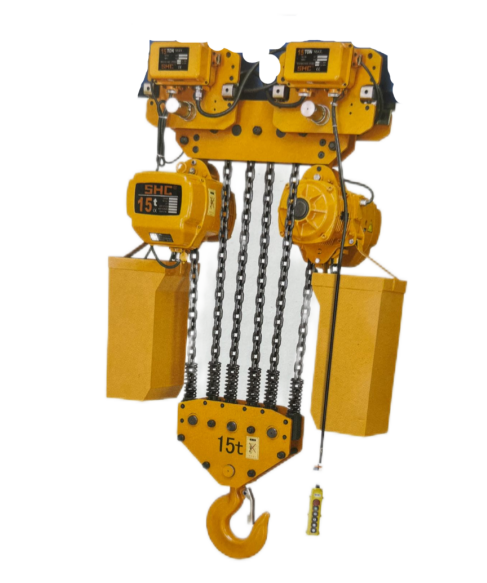

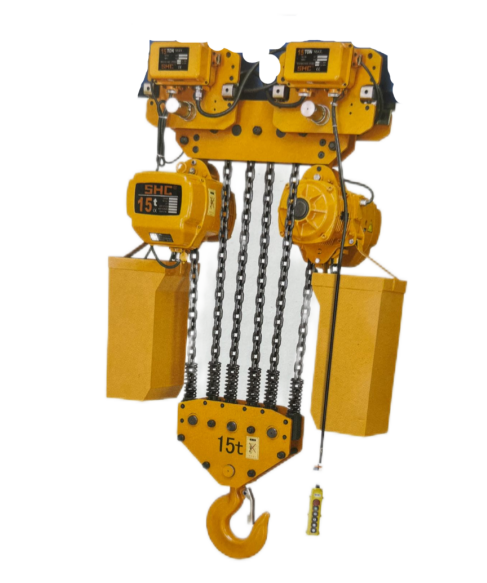

5. 15~25 tons large-tonnage running chain electric hoist

Double brake + mechanical safety clutch triple protection, the frame is strengthened by finite element analysis to strengthen the load-bearing structure.

Load classification: 15t/20t/25t (30t can be customized).

Lifting speed: 0.5~3m/min (infinitely variable speed).

Track requirements: I32~I45 I-beam (span ≤15m).

Optional oil-immersed gearbox to reduce noise to below 65dB.

Equipped with load dynamic monitoring system, real-time display of weight and eccentricity.

Port container parts lifting, heavy machinery assembly, generator set maintenance.

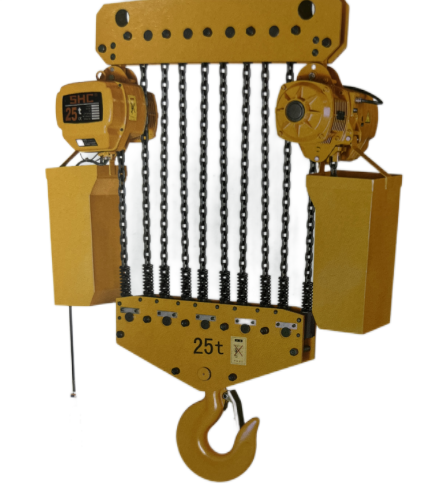

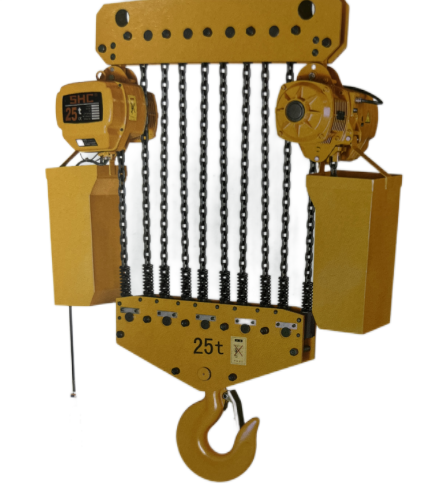

6. 15~25 ton fixed chain electric hoist

Cancel the walking mechanism and fix it directly to the steel frame structure through the flange, suitable for fixed-point heavy-load lifting.

Lifting height: customized (up to 50 meters).

Power redundancy: dual circuit power supply, support uninterrupted operation.

Protection level: IP65 (dustproof and waterproof).

Structural stability is improved by 30%, suitable for long-term heavy-duty conditions.

Maintenance cycle is extended to 800 hours (500 hours for conventional models).

Hydropower station gate maintenance, mine shaft equipment lifting, metallurgical furnace component replacement.

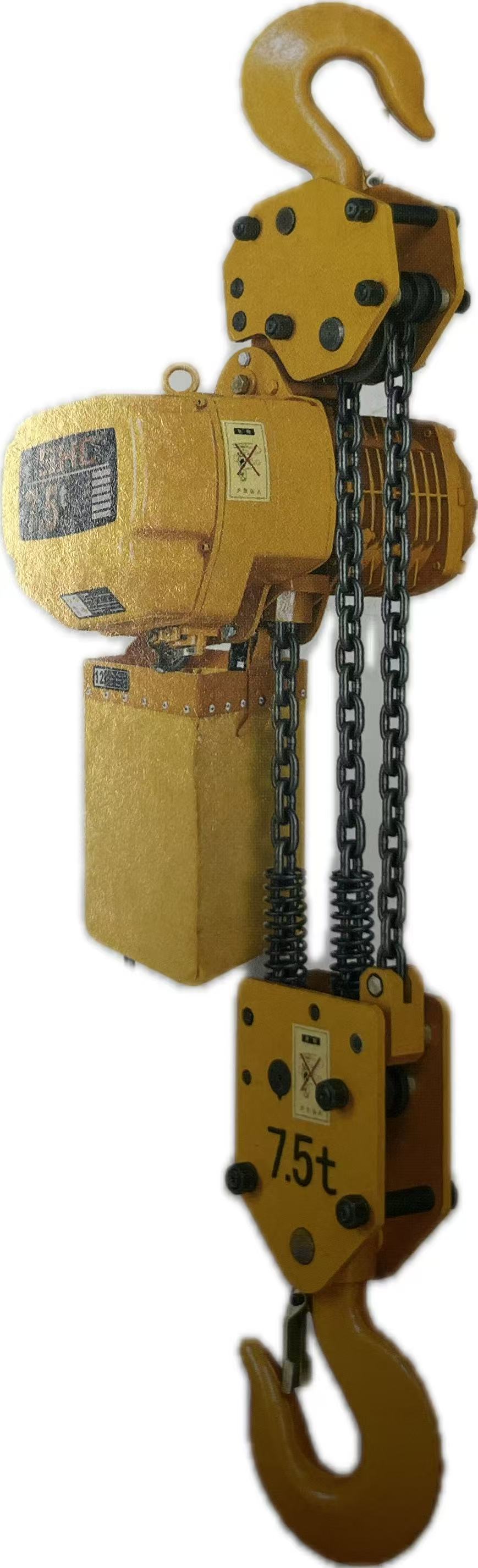

7. 10~15 tons low clearance chain electric hoist

Adopting a compact drum layout, minimizing the distance between the machine body and the lifting point, the clearance height is reduced by 40%~60%.

Applicable clearance: ≥1.2 meters (conventional models require ≥2.5 meters).

Chain guide design: anti-sway guide device to improve safety in narrow spaces.

Customization options: side-mounted motor (further save lateral space).

Equipment installation in underground garages, operations in ship cabins, and factory renovations with limited floor height.

Common product advantages

All series are equipped with overload protection, phase protection, and limit switches as standard, and are CE/ISO certified.

Adopting IE3 high-efficiency motors, energy consumption is reduced by 15%~20% compared with traditional hoists.

Modular design, key component replacement time ≤30 minutes, support IoT remote diagnosis (optional).

Light-load high-frequency scenarios: give priority to electric operation (3~5 tons) + frequency conversion control.

Heavy-load precision operations: 15~25 tons fixed type + laser positioning system is recommended.

Space-constrained environments: must select low-clearance models and evaluate side-mounting solutions.