Overview

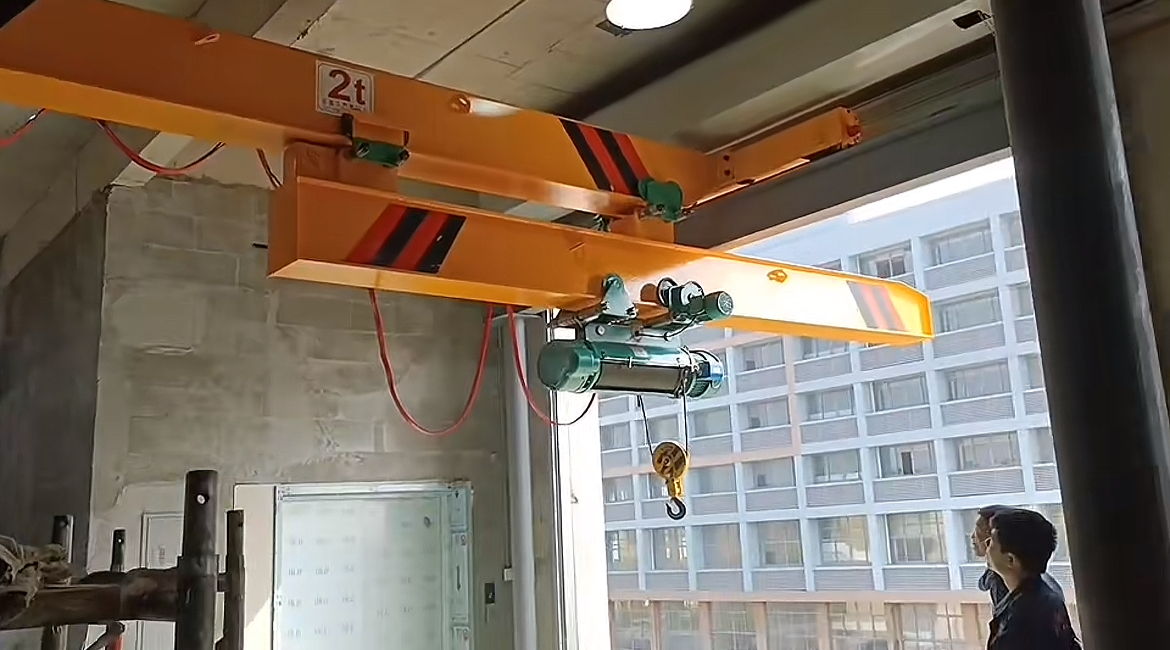

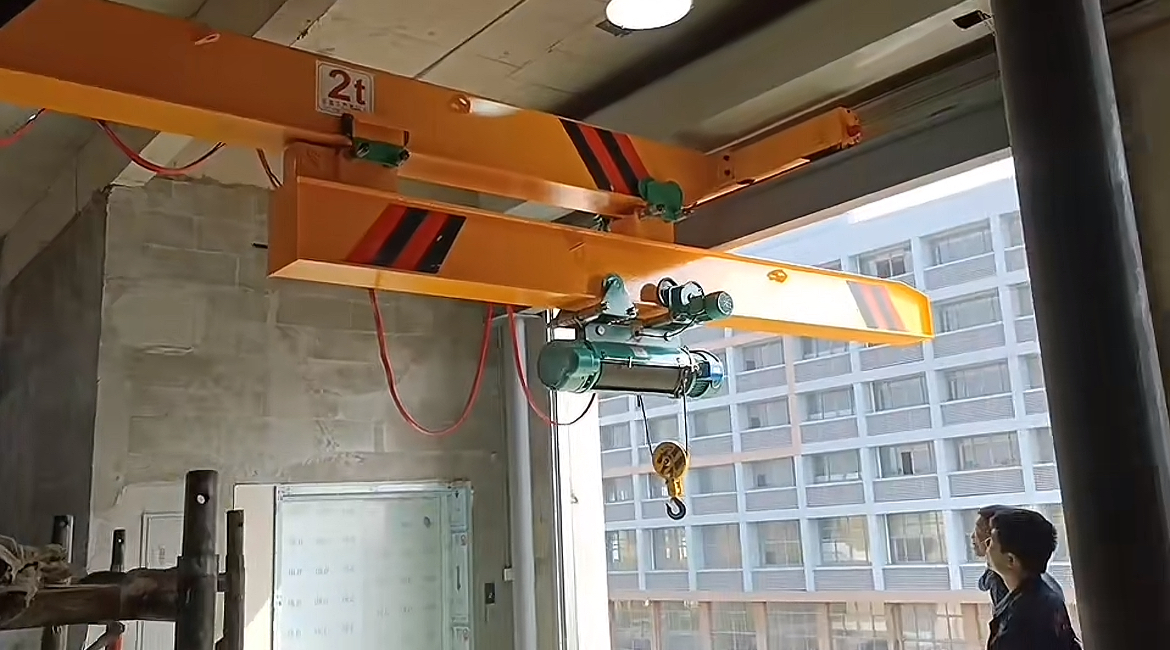

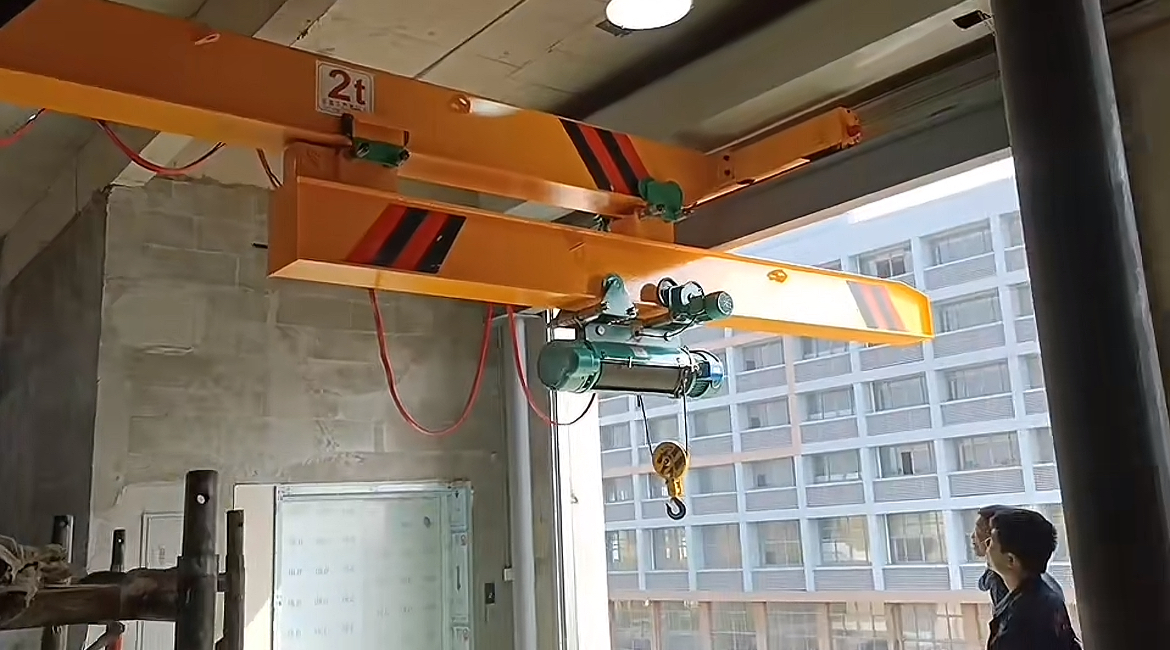

The telescopic crane is a highly efficient and flexible heavy-duty lifting equipment widely used in construction sites, logistics warehouses, ports, manufacturing, and large-scale equipment installation. Its core advantage lies in its telescopic structure design, which allows flexible adjustment of the boom length to adapt to lifting tasks of varying spans and heights, significantly improving operational efficiency and spatial adaptability.

Core Structural Components

1. High-strength box-type or dual-girder structure with internal torsion-resistant ribs for enhanced rigidity.

2. Anti-corrosion coating extends service life to over 20 years.

1.Multi-stage nested design driven by hydraulic cylinders, achieving a telescopic ratio of 1:3 for broad operational coverage.

2. Built-in limit switches and overload protection to prevent unauthorized overextension.

1. Wire rope hoist or electric chain hoist configurations with dual-speed/frequency conversion control, adjustable lifting speeds of 0.5–20 m/min.

2. Standard anti-sway technology reduces hook oscillation, ensuring precise operation.

1. Rail-Mounted: Heavy-duty steel rails with gear-driven systems for high-frequency fixed-site operations.

2. Wheeled/Crawler: Independent steering systems for superior mobility in mobile tasks.

1. Redundant safeguards: Overload limiter, emergency braking, wind speed monitoring, and lightning protection.

2. Real-time IoT-enabled data transmission for remote maintenance management.

Technical Specifications (Standard Model Example)

| Parameter | Value |

|---|

| Maximum Lifting Capacity | 50 tons |

| Duty Class | A5 (Heavy-duty) |

| Telescopic Boom Range | 15m–45m (5-stage extension) |

| Lifting Height | 6m–30m (customizable) |

| Lifting Speed | 0.5–10 m/min (variable frequency) |

| Travel Speed | 20–30 m/min (travel mechanism) |

| Power Supply | 380V/50Hz 3-phase AC |

| Total Weight | Approx. 28 tons |

Application

Construction: High-rise steel structure assembly, prefab component installation, concrete pumping support.

Port Logistics: Container handling, ship maintenance, bulk cargo transport.

Manufacturing: Heavy machinery assembly line operations, large mold relocation.

Energy Sector: Wind turbine blade installation, power plant equipment maintenance.

Emergency Rescue: Rapid deployment for obstacle removal in disaster zones.

After-Sales Service & Support

Global Warranty: 24/7 technical support with on-site assistance within 48 hours.

Lifecycle Management: Free operator training, routine inspections, and spare parts supply.

Custom Upgrades: Optional add-ons (e.g., cameras, laser positioning systems).