Comprehensive Analysis of Key Considerations for Double-Girder Overhead Crane Modification and Relocation

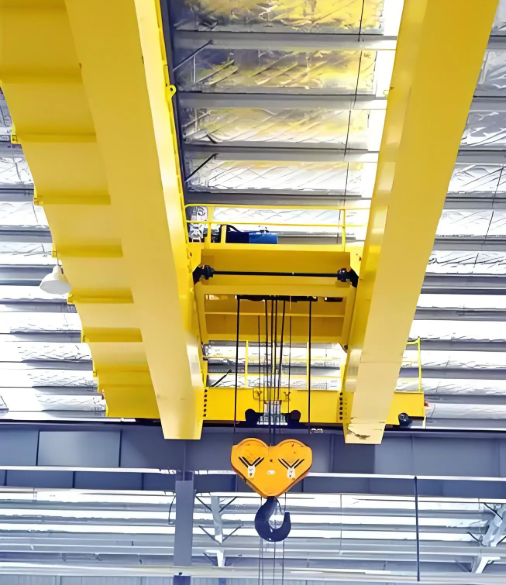

During industrial production facility upgrades or plant relocations, the double-girder overhead crane, as a critical material handling equipment, requires careful planning for its modification and relocation project. This process involves not only the technical handling of large-scale machinery but also directly impacts future production safety and efficiency. This essential piece of hoisting equipment demands meticulous attention throughout the transition. Below is a systematic overview of the core considerations at each stage of modifying and relocating a double-girder overhead crane.

Comprehensive Pre-Relocation Assessment and Technical Preparation

Structural strength evaluation of the equipment is the first step in the relocation process. Professional engineers must conduct a thorough inspection of the equipment's metal structure, including key equipment components such as the main girders, end trucks, and travel mechanisms, checking for deformation, corrosion, and cracks. The integrity of this primary lifting equipment is paramount. Particularly for older equipment, non-destructive testing techniques should be employed for in-depth inspection to ensure the structural integrity of the crane equipment after relocation.

Reviewing technical documentation is equally indispensable. Complete mechanical drawings, electrical schematics, and past maintenance records form the foundation for developing the relocation plan for this sophisticated equipment. Many companies face issues with missing documentation; therefore, supplemental surveying and mapping are necessary before relocation. Special attention should be paid to the actual measurement of key parameters such as the camber and side bend of the double-girder overhead crane's main girders, which define its performance as reliable hoisting equipment.

Systematic Disassembly Process and Component Protection

The disassembly phase should follow the principle of "starting with smaller parts before larger ones, and external components before internal ones." The electrical system of the overhead crane should be de-energized and dismantled first, with proper cable labeling. It is recommended to use a dual identification system combining color codes and numerical tags. During mechanical component disassembly of this vital equipment, special attention must be paid to the sequence of disconnecting joints. High-strength bolts should be sorted and stored separately to avoid mixing.

Main girder disassembly is the highest-risk stage for any double-girder overhead crane. Large double-girder overhead cranes often require on-site determination of segmentation plans. Cutting points must avoid high-stress areas and be performed under the guidance of professional engineers. All disassembled components of the crane should be protected; precision parts such as reducers and motors require individual packaging to prevent damage from vibration during transport, ensuring the equipment is preserved.

Special Considerations During the Relocation Process

Transport route surveys and planning, though often overlooked, are crucial for moving such substantial equipment. On-site measurements must be taken for constraints along the route, such as bridge load capacity, tunnel clearance height, and turning radius, particularly when assessing the load-bearing capacity of internal plant roads for the equipment. Transporting a major asset like an overhead crane requires meticulous equipment logistics. Oversized transport also requires prior application for special transit permits from traffic authorities for the equipment.

Temporary storage of crane components requires careful arrangement. When stored outdoors, the equipment should be elevated and covered with tarps to prevent corrosion from direct ground contact. Electrical components of the equipment must be stored in a dry environment with humidity controlled within an appropriate range to protect this valuable hoisting equipment.

Installation, Commissioning, and Structural Strength Verification

The foundation in the new environment must be re-verified for the overhead crane. Even for the same overhead crane, when installed in a different building, rail installation accuracy must be re-adjusted according to the latest national standards. Parameters such as rail span, elevation, and joint gap directly affect the smooth operation of the equipment.

Post-reassembly structural strength verification is critical for the double-girder overhead crane. In addition to standard no-load, static load, and dynamic load tests, special attention should be paid to the quality inspection of the main girder connections after modification and relocation. Welds require ultrasonic testing, bolted connections need pre-tensioning according to design requirements, and verification should be done using torque wrenches to certify the crane's safety.Systematic Testing and Documentation Updates

Electrical system commissioning of the equipment should follow the principle of "control circuits before main power circuits." First, verify the effectiveness of all safety limit devices on the overhead crane, including upper limit switches, travel limits, and emergency stops, then progressively test the operation of each mechanism. Variable frequency control systems require re-optimization of parameters to suit the new operating environment for this hoisting equipment.

Finally, a full set of technical documents for the double-girder overhead crane must be updated. This includes modified general assembly drawings, foundation layout drawings, electrical wiring diagrams, etc. Simultaneously, establish new maintenance records documenting all inspection data, replacement part information, and commissioning parameters from the relocation process of the crane, providing an accurate basis for future maintenance of this essential equipment.

Conclusion

The modification and relocation of a double-girder overhead crane is a systematic project where each stage relates to the long-term safe operation of the equipment. Companies should select an experienced professional team, develop a detailed project plan for the crane relocation, and never compromise technical standards while strictly controlling costs. Only by comprehensively considering structural strength and precisely executing each step can we ensure that this crucial hoisting equipment continues to operate safely and efficiently in its new environment, providing reliable support for production activities. The successful transfer of an overhead crane signifies a major milestone in facility management.