10 Practical Tips to Extend Your Suspension Single Girder Crane's Lifespan

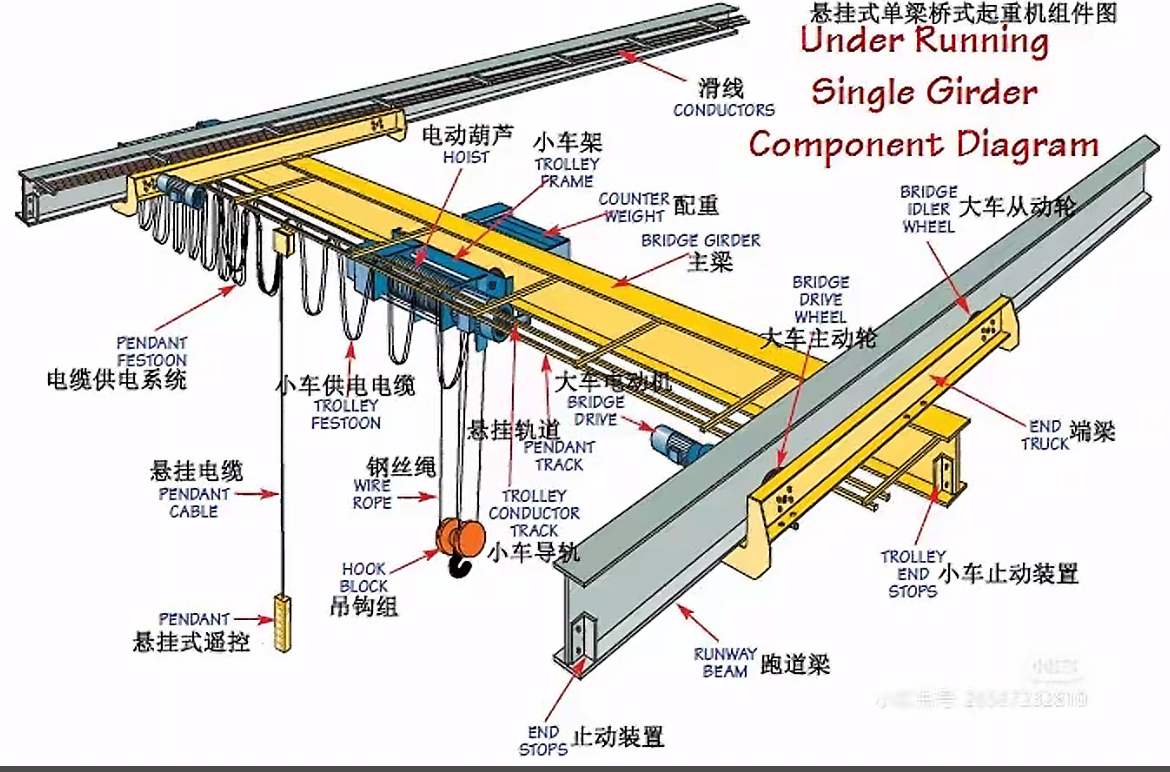

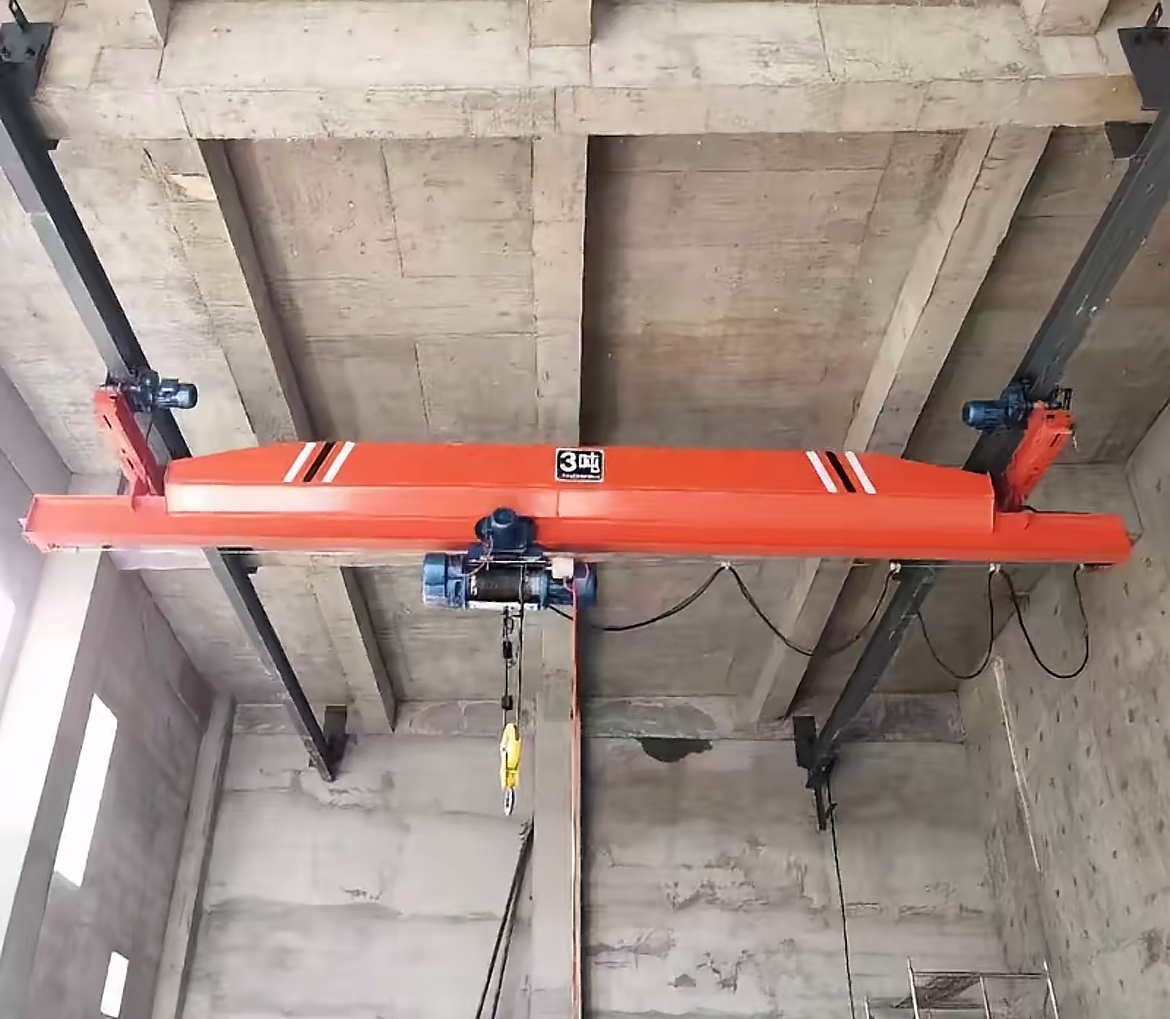

Suspension single girder cranes are vital for material handling in workshops and warehouses. Their lifespan directly impacts productivity and costs. While simpler than overhead travelling cranes, their longevity relies on proper use and maintenance. These 10 tips will significantly extend service life:

Standardize Operation: Avoid Overloads & Side Pulls

Strictly adhere to the crane's rated load capacity – this is non-negotiable. Every instance of overloading inflicts significant damage on the main girder, end carriages, electric hoist, and supporting structure, drastically accelerating fatigue failure. Similarly, pulling loads diagonally generates substantial lateral forces, severely threatening the stability of the suspension single girder crane's runway, wheels, and overall structure.

Operate Smoothly: Minimize Shock

Operate the crane with smooth acceleration, consistent speed, and gentle deceleration. Sudden starts or abrupt stops create high dynamic shock loads, causing cumulative damage to the crane’s bridge travel mechanism, trolley travel mechanism, and electrical system.

Clean Regularly: Control Environment

Remove dust, oil, chips, and debris from runways, wheels, hoist trolley, and girder. Contamination accelerates wear and impairs electrical component function. Essential for suspension single girder cranes and overhead travelling cranes in harsh environments.

Lubricate Correctly: Critical Protection

Follow the manual for intervals, points, and lubricant types. Key areas: bridge & trolley wheel bearings, hoist gearboxes, wire rope (if used), hook bearings. Proper lubrication prevents premature bearing failure and wear.

Maintain Runway Precision: Essential Foundation

Periodically inspect the wear condition (especially flanges and treads), check for cracks, and ensure smooth rotation of both bridge and trolley wheels. Severely worn or damaged wheels can harm the runway and overload the drive mechanisms. Adjust wheels promptly to ensure proper contact with the runway.

Inspect Wheels: Prevent Costly Damage

Regularly inspect and ensure the crane runway's straightness, levelness, and gauge accuracy. Runway sagging, bending, or misaligned joints significantly increase wheel rolling resistance, leading to abnormal wheel wear or even derailment, severely impacting the smooth operation and lifespan of both suspension single girder cranes and overhead travelling cranes.

Monitor Lifting Media: The Safety Lifeline

Conduct daily inspections of wire rope (or chain), focusing on wear, broken wires, deformation, corrosion, and lubrication condition. Replace them strictly according to discard criteria; never operate with compromised components. This is the lifeline for safe operation of both single girder cranes and overhead travelling cranes.

Service Electrical Systems: Ensure Reliability

Keep control boxes clean/dry. Check terminals, clean contacts, test safety limit switches (hoist, travel). Ensure motors run smoothly without noise/overheating. A robust electrical system is crucial for reliable operation.

Check Structure Annually: Catch Issues Early

Schedule annual professional inspections of the main girder, end carriages, and suspension points. Focus on welds, bolts, high-stress areas for deformation, cracks, or corrosion. Early detection is key for suspension single girder crane and bridge crane integrity.

Train Operators & Manage Rigorously

Ensure certified, trained operators. Implement systems for equipment checks, maintenance logs, and repair records. For critical suspension single girder cranes or complex overhead travelling cranes, consider condition monitoring and predictive maintenance.

Maximizing Investment Value

The cost-effective suspension single girder crane is a preferred solution. Integrating these 10 tips reduces failures, prevents downtime, and extends the service life of your single girder crane, maximizing ROI. Whether using a basic suspension single girder crane or a robust overhead travelling crane, preventive maintenance and standardized operation are fundamental for safe, reliable, long-term performance. Scientific upkeep ensures enduring equipment vitality.