Explosion-Proof Hoist vs. Conventional Electric Hoist: The Ultimate Selection Guide

In factories, warehouses, or hazardous sites like chemical plants and refineries, choosing the right electric hoist is critical for safety and productivity. Faced with explosion-proof hoists and conventional electric hoists, decision-makers must weigh absolute safety against cost-efficiency. This guide clarifies the differences to find the optimal balance.

Core Differences: Safety Engineering

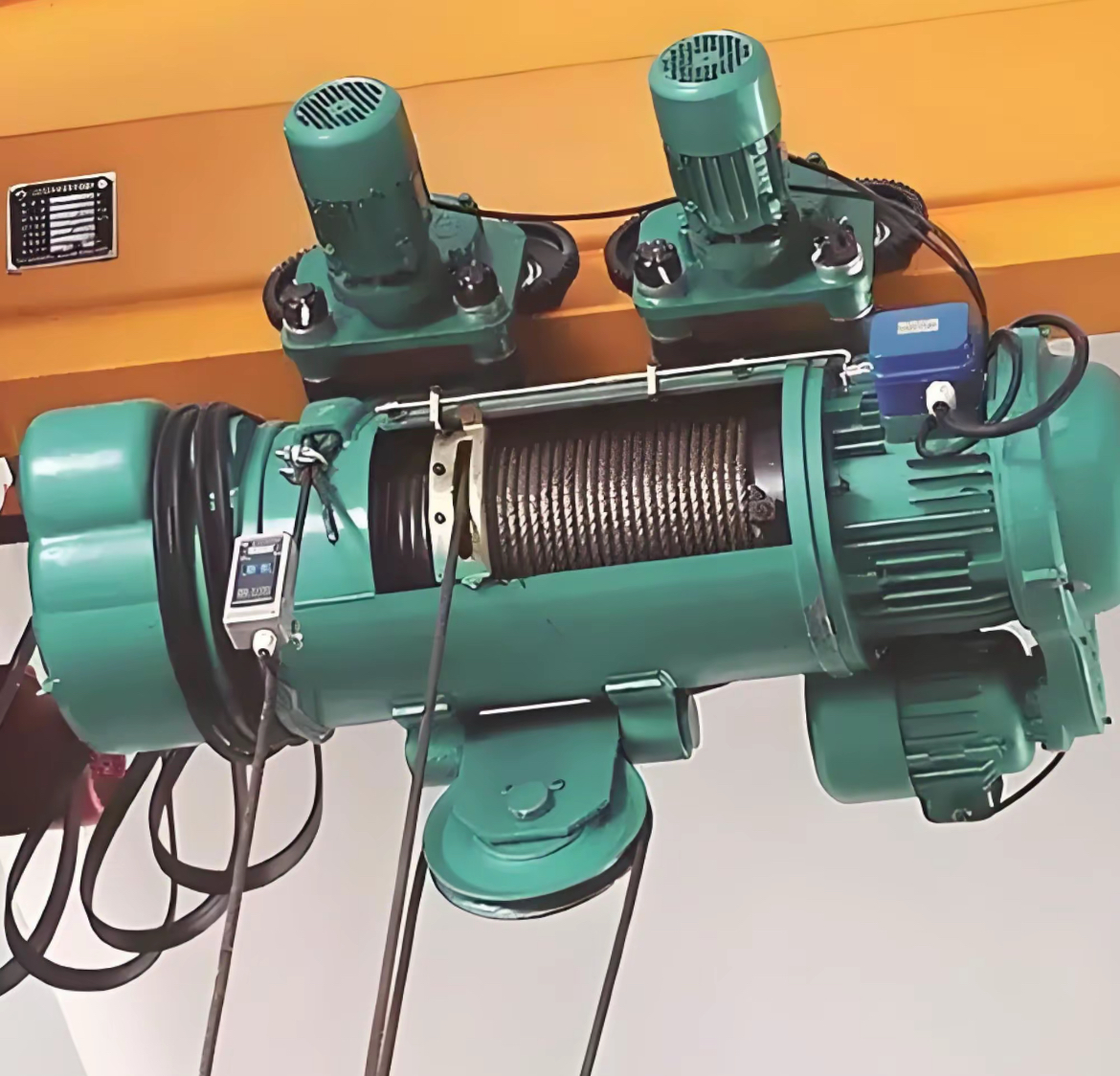

Conventional Electric Hoist: The industrial standard. Designed for durability, capacity, and ease of use in non-hazardous areas like standard workshops or warehouses. Its straightforward design offers reliability and cost-effectiveness, making this electric hoist a popular choice where no explosion risks exist.

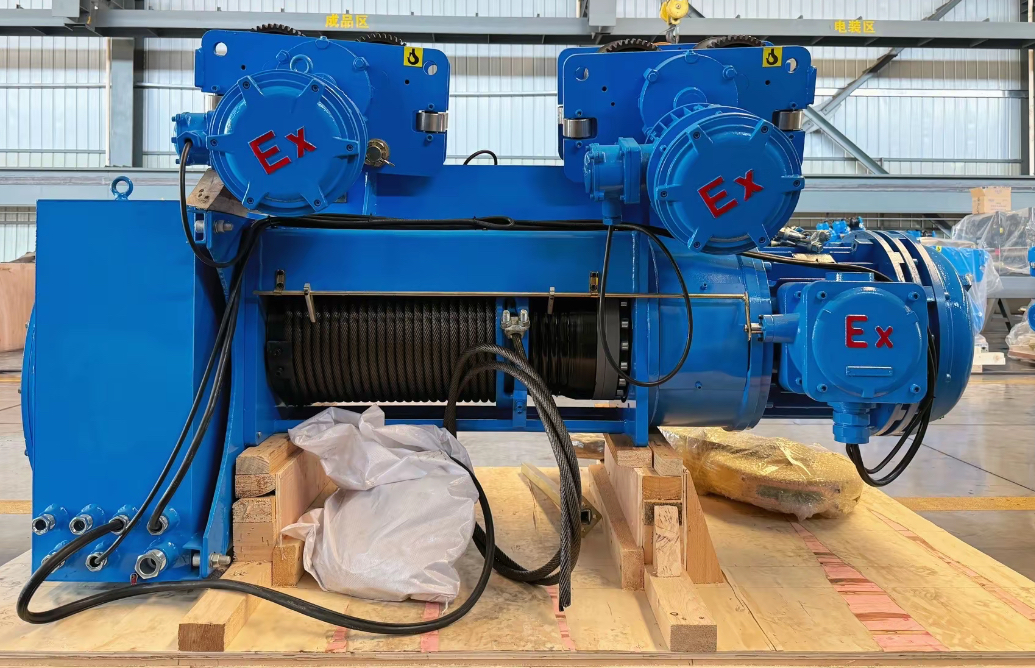

Explosion-Proof Hoist: Built for danger zones. Its purpose is to prevent sparks or heat from igniting flammable gases (methane, hydrogen), dusts (coal, flour), or vapors. This requires rigorous design and explosion-proof certification (e.g., Ex d IIC T4 Gb) using methods like flameproof enclosures (Ex d), intrinsically safe circuits (Ex i), and increased safety (Ex e). Every component, from special gearboxes to spark-free brakes and sealed junction boxes, forms a critical safety barrier. Selecting an explosion-proof hoist is essential protection in high-risk environments.

Key Comparison: Safety, Efficiency, Cost.

Safety: The Critical Divide

Conventional Electric Hoist: Safe and reliable in non-explosive settings, meeting standard safety requirements. Protections like overload stops suffice for typical risks.

Explosion-Proof Hoist: Mandatory for explosive atmospheres. Its design and explosion-proof certification minimize ignition risks from operation or faults. It's a legal and safety necessity in refineries, chemical plants, or grain silos.

Efficiency & Performance: Subtle Trade-offs

Speed & Load: High-quality explosion-proof hoists match the lifting performance of equivalent conventional electric hoists.

Heat & Duty Cycle: Explosion-proof enclosures can limit heat dissipation. Some models may require monitoring during heavy use or have stricter duty cycles. Conventional electric hoists generally handle heat more directly.

Cost: Investment vs. Value

Purchase: Explosion-proof hoists cost significantly more (1.5-2x+) due to materials, complexity, and explosion-proof certification.

Installation: Hazardous area installation requires certified contractors and compliant wiring, adding cost.

Maintenance: Parts and training are costlier for explosion-proof hoists, but this pales against preventing catastrophic accidents. Conventional electric hoists offer clear cost advantages in safe areas.

Precise Selection: Environment Dictates Choice

Choose Explosion-Proof Hoists When:

Flammable gases/vapors (e.g., petrochemical zones, paint booths) or combustible dusts (e.g., grain silos, coal handling) are present.

Regulations (OSHA, ATEX, GB 3836) mandate it.

Explosion consequences would be catastrophic.

Choose Conventional Electric Hoists When:

The environment is confirmed free of explosion risks (e.g., machining shops, clean warehouses, assembly lines).

Cost sensitivity is high and safety risk is zero.

This electric hoist type offers the best lifting equipment selection value.

Additional Factors

Environment: Consider temperature, humidity, corrosion, and IP rating. Explosion-proof models often have robust baseline protection.

Control: Options include pendants, certified explosion-proof remotes, or VFD for precision.

Brand & Support: Choose established brands with strong local support, especially for explosion-proof hoist maintenance and certification.

Compliance: Ensure all electric hoists meet local regulations and possess necessary explosion-proof certification.

Conclusion

Safety is paramount in electric hoist selection. Explosion-proof hoists provide vital protection where mandated, justifying their cost. Conventional electric hoists deliver efficient, economical lifting in safe zones. Smart choices stem from accurate hazard identification and strict compliance. Balancing safety and efficiency defines modern industrial practice. Every correctly selected hoist powers a safer, more productive future.