Overview

Sliding contact lines (also known as safety sliding contact lines or conductor rails) are devices designed to provide continuous power transmission for mobile equipment. They are widely used in cranes, automated production lines, logistics and storage systems, electric amusement rides, and other applications requiring uninterrupted power supply. By utilizing sliding contact technology, these systems deliver stable and safe electrical energy to mobile equipment, replacing traditional cable-dragging methods. They offer advantages such as high efficiency, durability, and low maintenance costs.Based on structural design and application scenarios, sliding contact lines are primarily categorized into Single-Pole Sliding Contact Lines and Seamless Cylindrical Sliding Contact Lines.

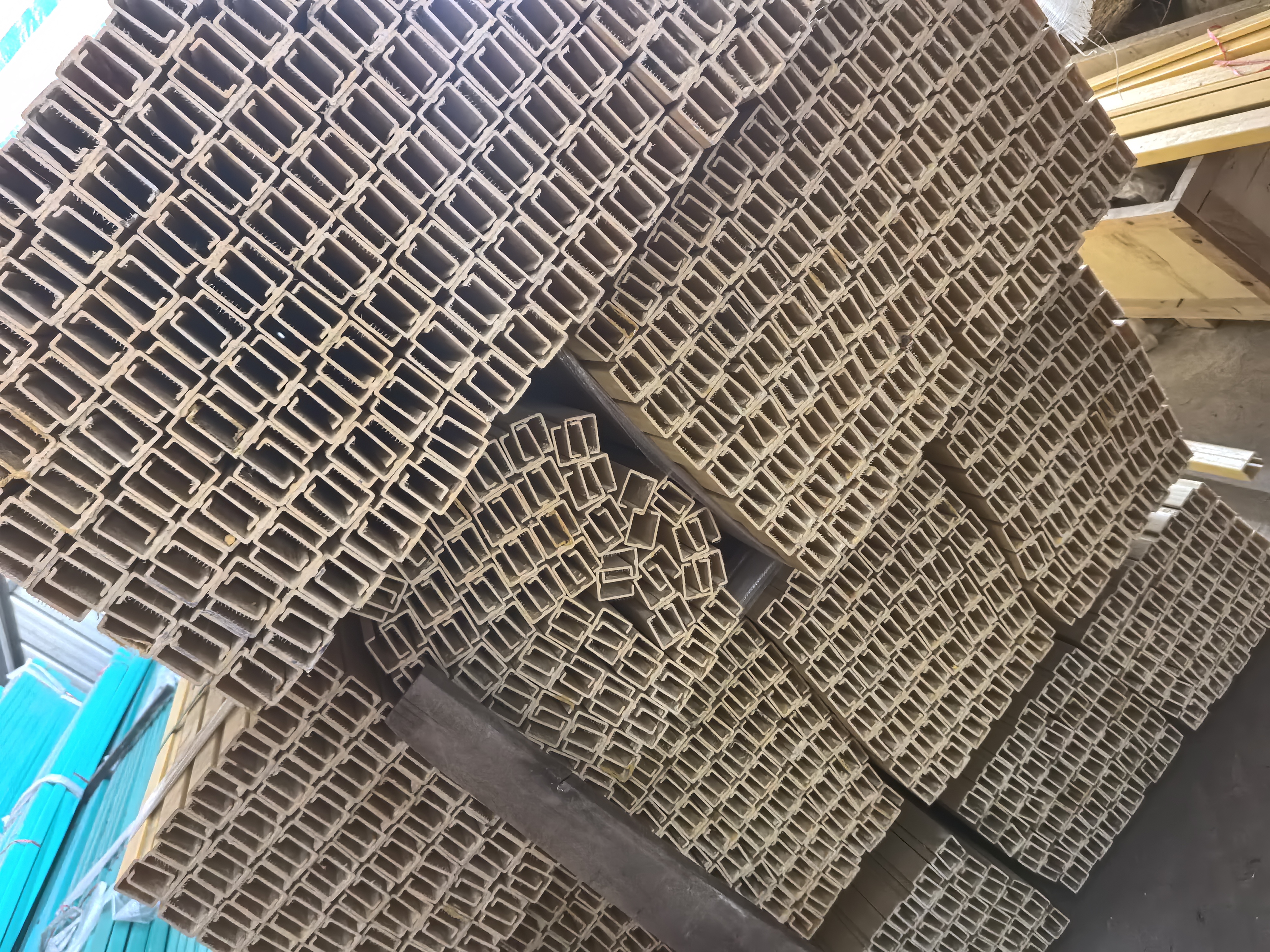

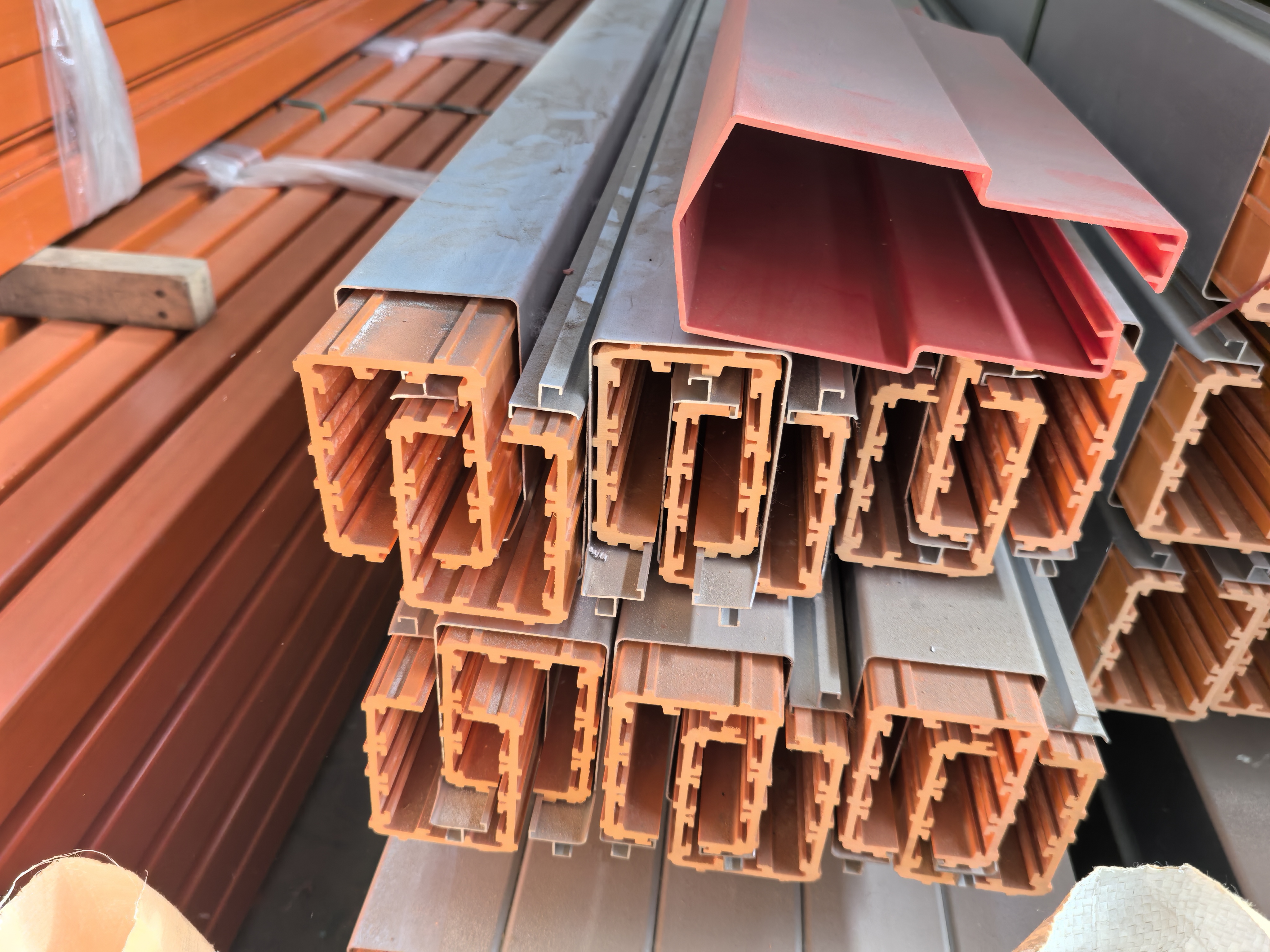

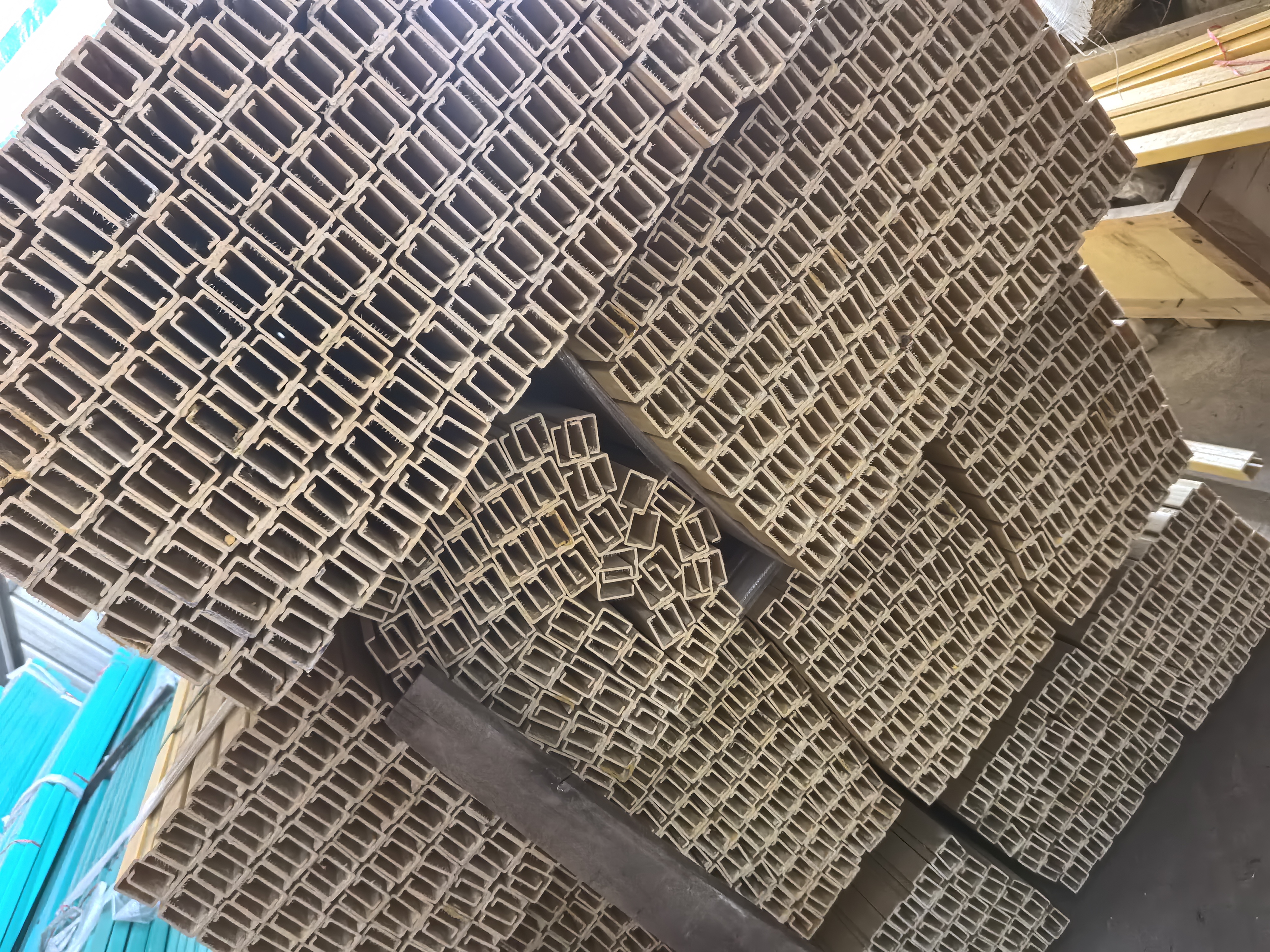

Single-Pole Sliding Contact Line

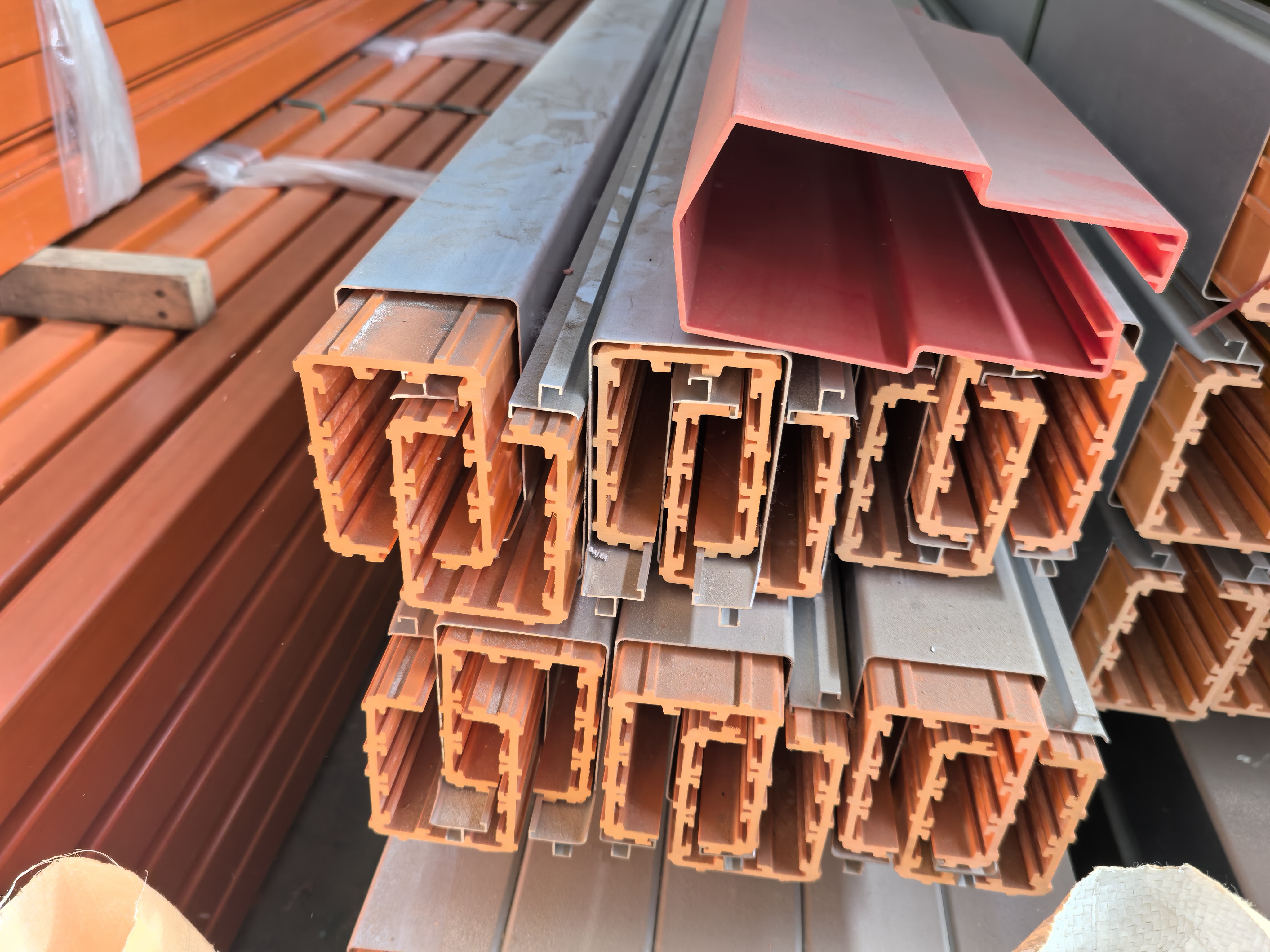

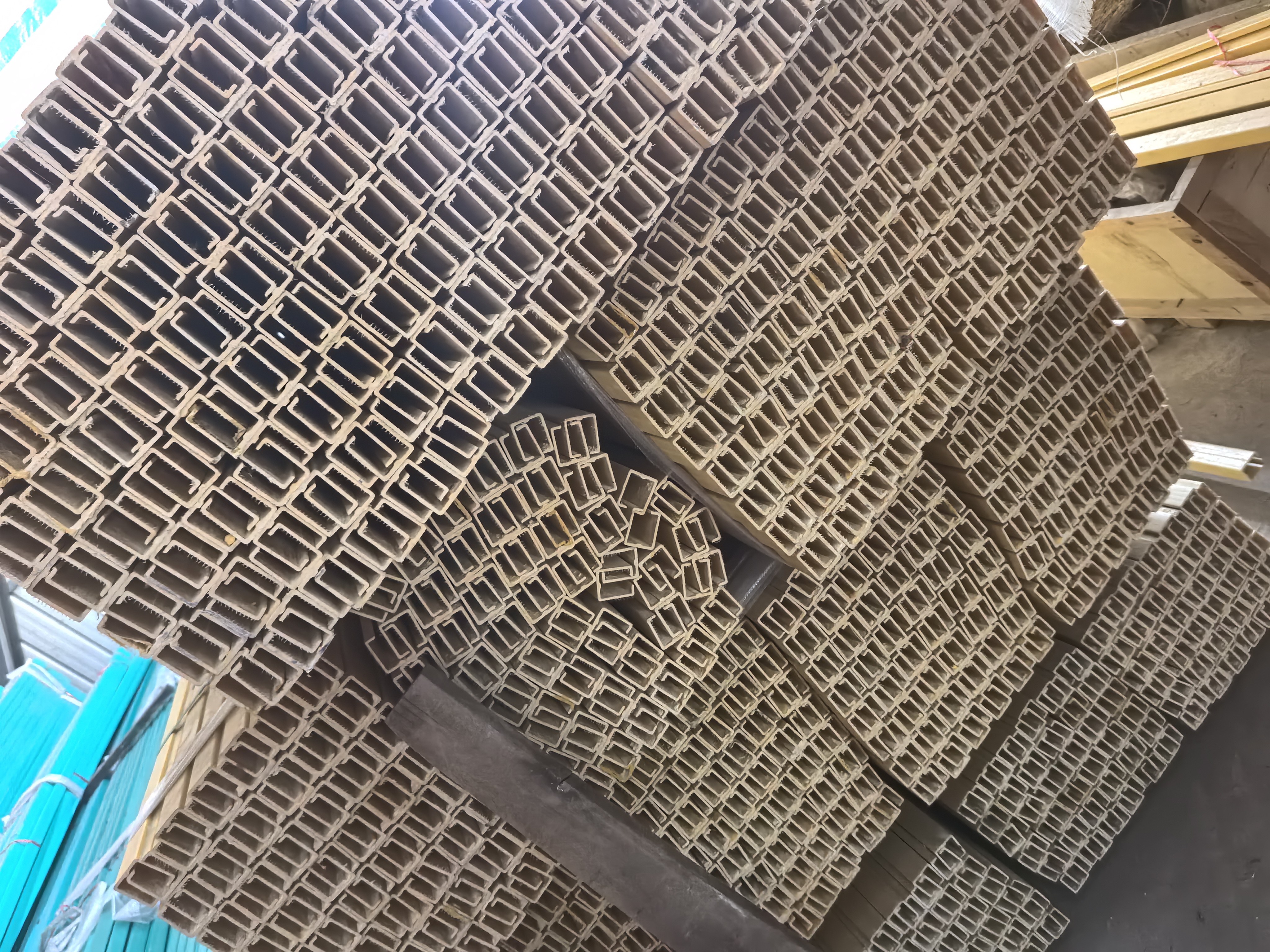

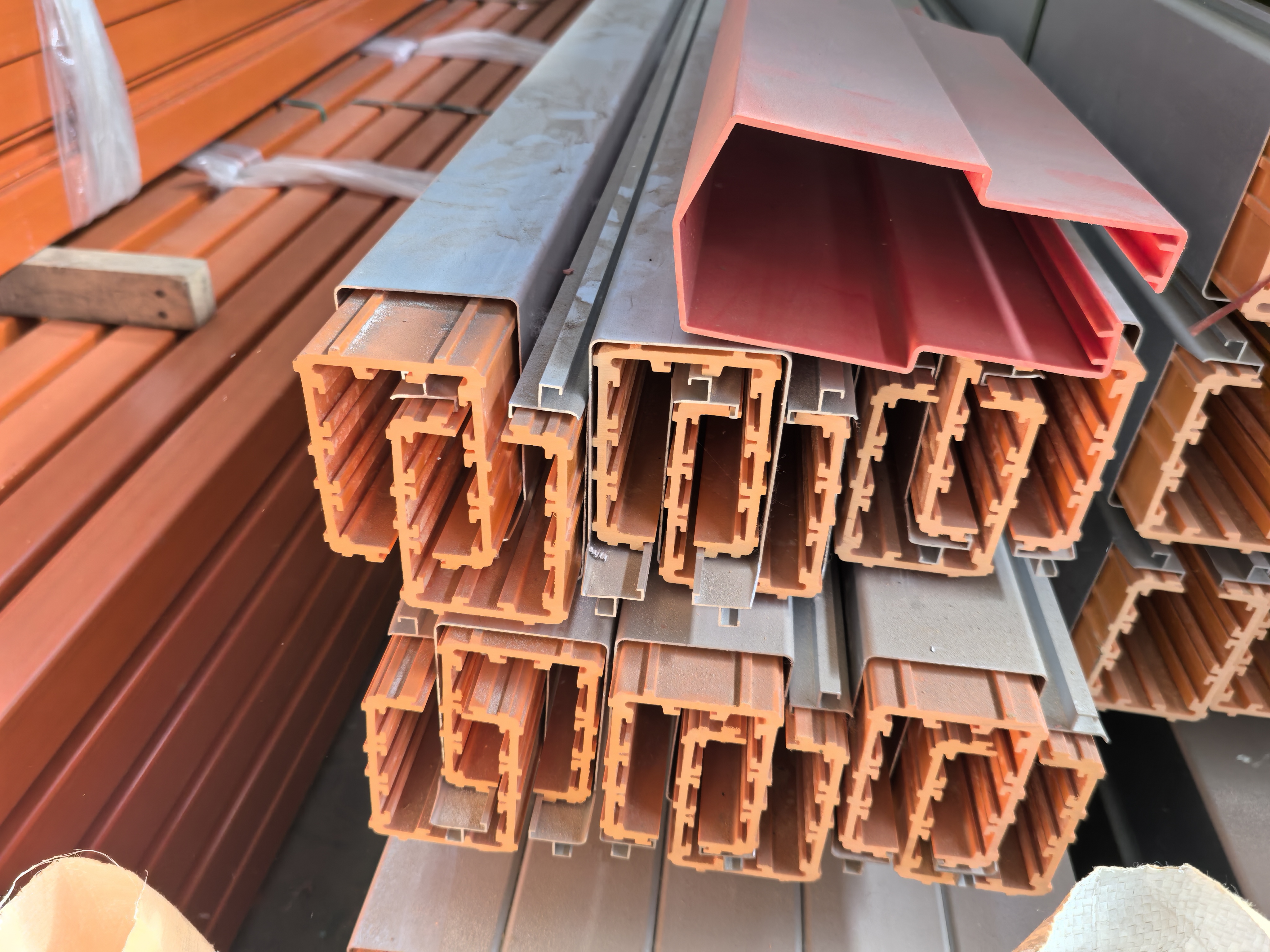

Single-pole sliding contact lines consist of a single conductive rail, an insulated protective housing, and a current collector.

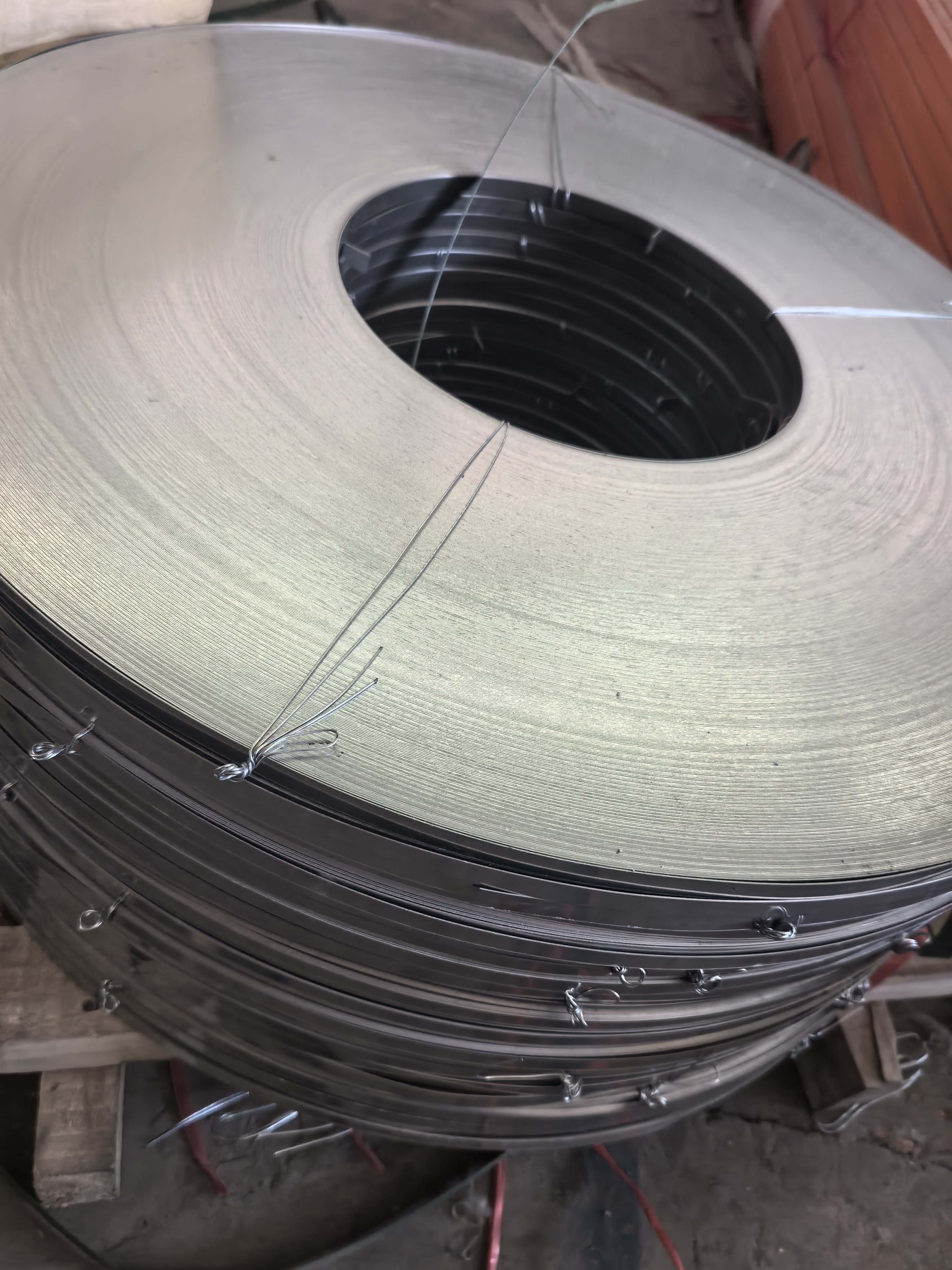

1. Conductive Rail: Made of high-purity T2 copper or aluminum alloy, with tin or silver plating to enhance conductivity and oxidation resistance.

2. Housing: Constructed from high-strength PVC or flame-retardant engineering plastics, achieving IP54 protection for dust and water resistance.

3. Current Collector: Utilizes carbon brushes or copper-based composite materials to ensure stable contact and minimize arcing and wear.

1. Modular Design: Standardized 6-meter segments enable rapid assembly via connectors, adaptable to varying span requirements.

2. High Conductivity: Copper conductors achieve ≥98% conductivity, suitable for high-current (50A–1000A) and medium-voltage (up to AC 600V) applications.

3. Environmental Resilience: Operates reliably in temperatures ranging from -40°C to 80°C and humidity ≤95%.

4. Low Impedance: Optimized conductor cross-section reduces energy loss, improving energy efficiency.

1. Industrial workshops: Overhead cranes, gantry cranes, and electric hoists.

2. Ports and terminals: Container cranes, loading/unloading equipment.

3. Automated systems: Material handling lines, AGV power supply.

1. Lifespan exceeds 10 years, far surpassing cables (1–3 years).

2. Simplified installation and maintenance, eliminating frequent cable replacements.

3. Enhanced safety by avoiding short-circuit risks from dragging cables.

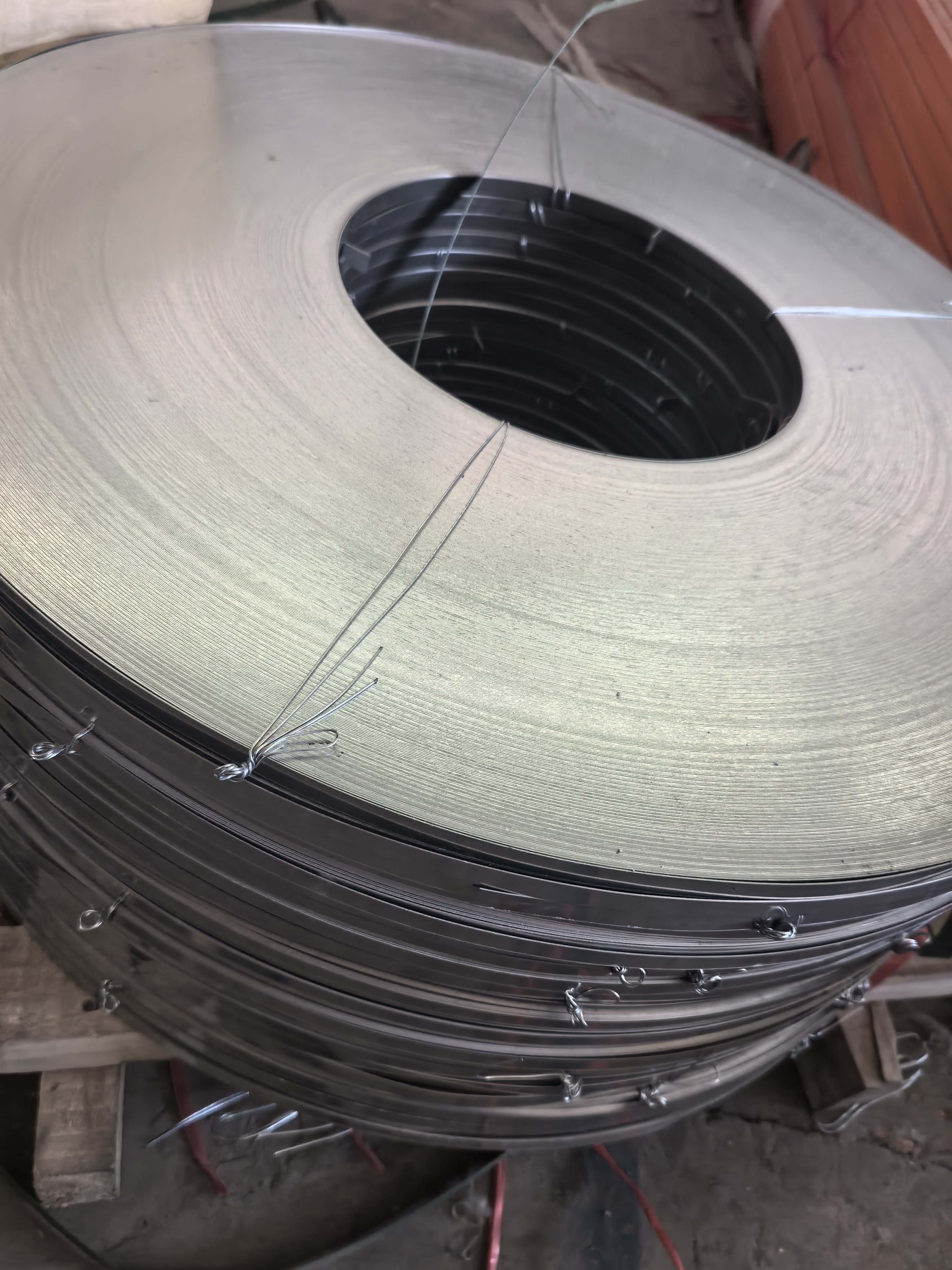

Seamless Cylindrical Sliding Contact Line

Seamless cylindrical sliding contact lines feature a one-piece cylindrical conductor with no joints or seams.

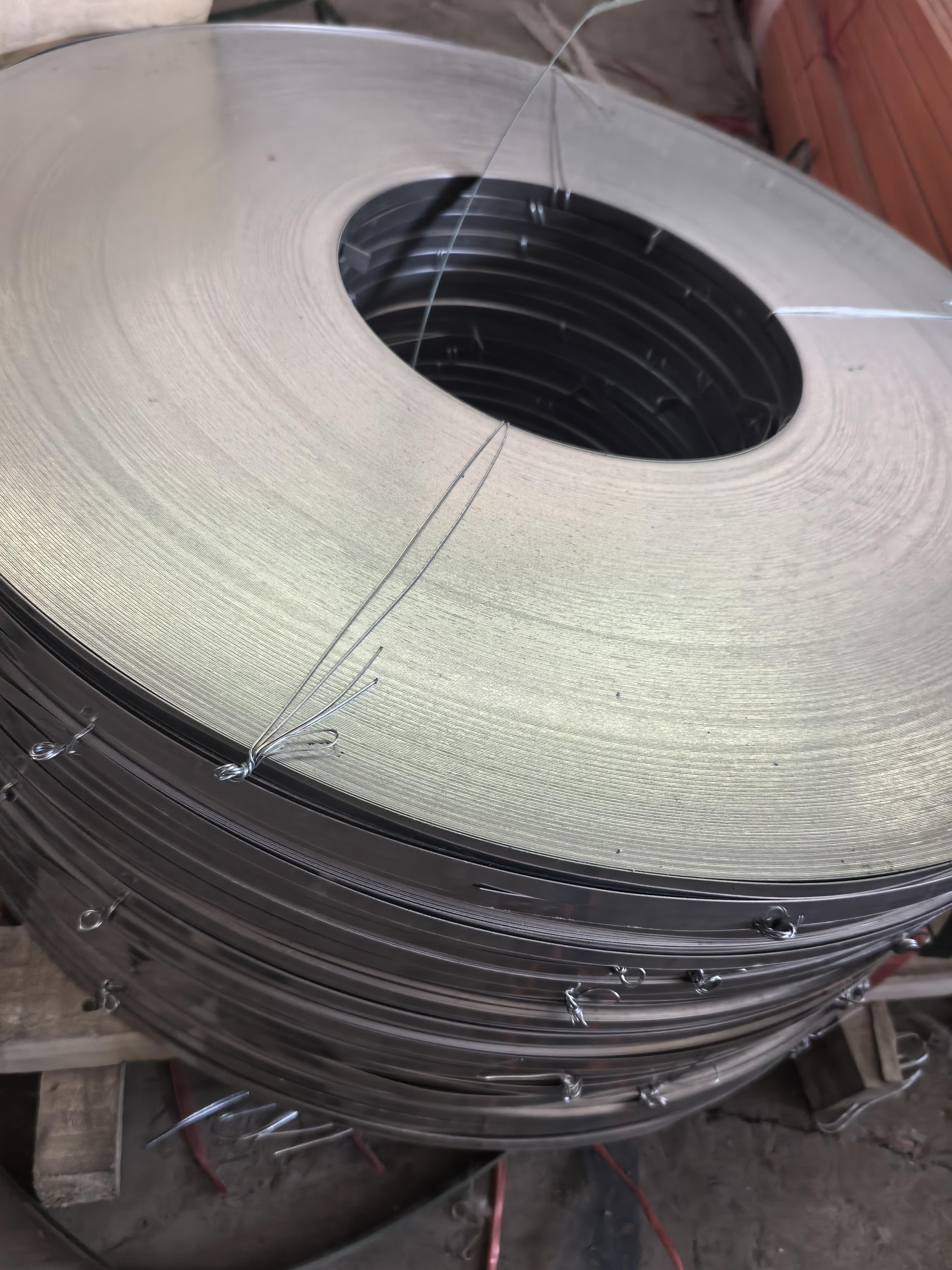

1. Conductor Material: High-conductivity copper alloy or stainless steel, coated for wear resistance.

2. Insulation Layer: Embedded epoxy resin or ceramic coating for high-temperature and aging resistance.

3. Mounting Brackets: Lightweight aluminum alloy brackets for horizontal or vertical installation.

1. Seamless Design: Eliminates power interruptions, contact sparks, and voltage fluctuations.

2. Superior Protection: IP67-rated for dustproof, waterproof, and oil-resistant performance in harsh environments.

3. Low EMI: Enclosed structure minimizes electromagnetic interference, ideal for precision equipment.

4. Maintenance-Free: Self-cleaning design ensures uniform wear, with a lifespan of up to 15 years.

1. Cleanrooms: Semiconductor production lines, pharmaceutical sterile facilities.

2. Outdoor heavy-duty equipment: Mining machinery, bulk material handlers.

3. High-precision systems: CNC machines, laser cutters.

1. Single-Pole: Ideal for standard industrial environments requiring cost-effective, high-current solutions.

2. Seamless Cylindrical: Recommended for high-speed, high-protection, or precision applications, including outdoor and harsh conditions.

1. Compliance: Meets IEC 61537 and GB/T 7251.5 standards.

2. Customization: Specialized bends, low/high-temperature variants, explosion-proof models.

3. Warranty: 3 years for single-pole lines; 5 years for seamless cylindrical lines.