Overview

Rope Guide is a mechanical device used to guide, position and protect wire ropes, cables or synthetic fiber ropes. It is widely used in cranes, winches, lifting equipment, ship deck machinery, mining equipment and stage hoisting systems. Its main function is to ensure that the rope is wound neatly and orderly on the drum or pulley to avoid rope wear, breakage or equipment failure caused by deflection, overlap or friction, thereby improving operation safety and equipment life.

Product structure and composition

Made of high-strength alloy steel, stainless steel or engineering plastics, it has good impact resistance and corrosion resistance, and can adapt to different environments (such as humid, high temperature or corrosive places).

1. Guide wheel design: The surface is usually covered with polyurethane (PU), nylon or rubber material to reduce friction with the rope and reduce noise.

2. Guide groove structure: The arc groove is customized according to the rope diameter to accurately guide and limit the lateral displacement of the rope.

Built-in precision bearings ensure that the guide wheel can rotate flexibly, reduce running resistance, and adapt to high-speed or heavy-load conditions.

Equipped with adjustable brackets or slide rails, it supports horizontal or vertical position adjustment to adapt to different drum widths and rope arrangement requirements.

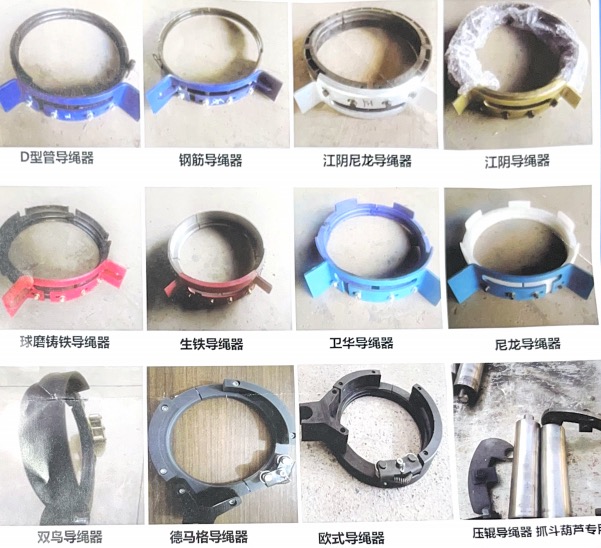

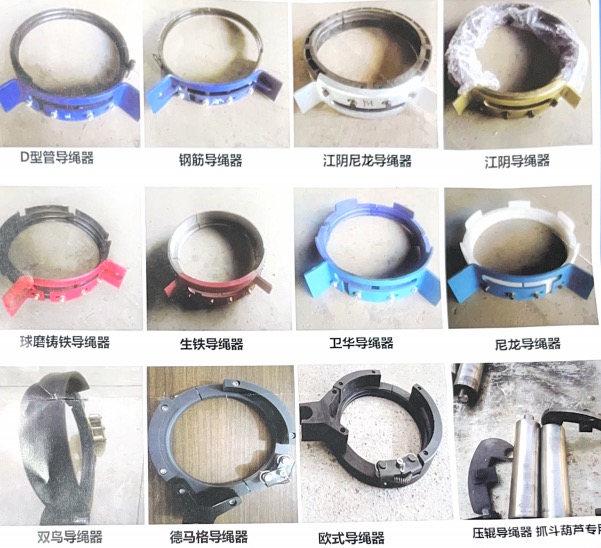

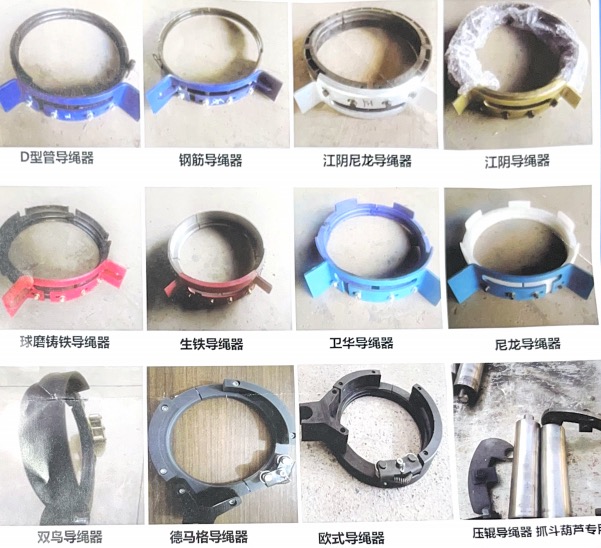

Product types and applicable scenarios

1. Features: simple structure, low cost, suitable for low-speed and light-load scenarios.

2. Applications: small winches, manual hoists, stage lighting hoisting.

1. Features: 360° rotation design, dynamic tracking of rope direction, and prevention of twisting and wear.

2. Applications: port cranes, tower cranes, large lifting platforms.

1. Features: Move synchronously with the drum to ensure that the ropes are closely arranged layer by layer to avoid rope disorder.

2. Applications: mining winches, heavy winches for offshore platforms.

1. Features: Add protective baffles or limiters to prevent accidents caused by rope slipping out of the groove.

2. Applications: high-speed elevators, cable car traction systems.

Core technology and performance parameters

1. Applicable rope diameter range: Φ5mm~Φ80mm (customizable according to needs).

2. Maximum load capacity: 1 ton~100 tons (based on material and structural design).

1. Wear-resistant layer life: PU guide wheel can reach more than 500,000 cycles (no abnormal wear).

2. Working temperature: -40℃~+120℃ (special materials can be extended to -60℃~+200℃).

1. Passed ISO 4309 (crane wire rope inspection standard), CE certification and explosion-proof certification (Ex d IIC T4).

2. Static safety factor ≥4 times, dynamic safety factor ≥2.5 times.

Jinghe professional support

Although the rope guide is a small accessory, it is a key component to ensure the safe and efficient operation of heavy equipment. Jinghe Crane's products have served many key engineering fields around the world with precision design, high-quality materials and strict quality control. If you need customized solutions or technical consultation, please contact our professional team, we will provide you with professional support!