As summer temperatures soar, industrial workshops face severe operational challenges. For businesses reliant on heavy machinery, crane stability and safety become paramount. High-temperature environments often lead to unstable operation, reduced efficiency, and unexpected shutdowns of crane systems. Failures in double-girder overhead crane motors are particularly prevalent under these conditions. This article details practical motor overheating protection strategies to enhance equipment resilience and safety.

1.Impact of High Temperatures on Cranes

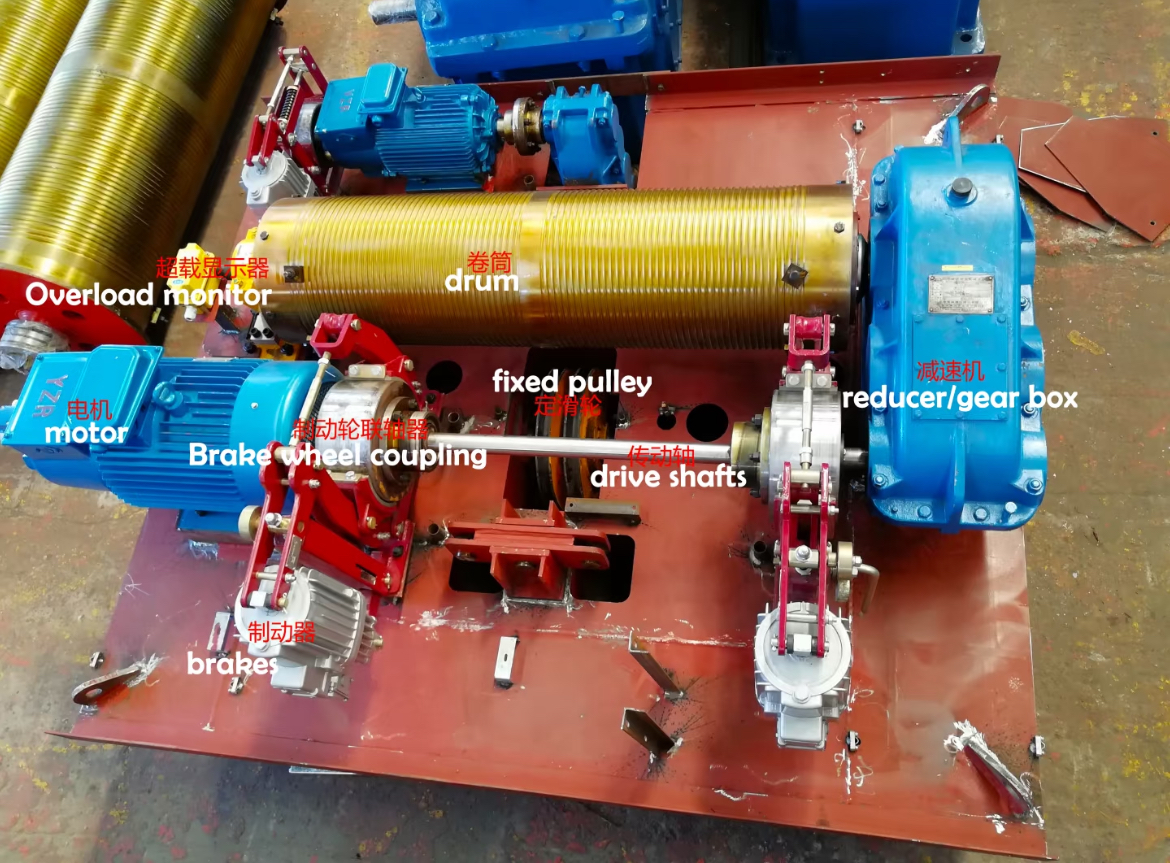

In enclosed or poorly ventilated workshops exceeding 40°C, critical crane components like motors, brakes, and gearboxes suffer. Double-girder overhead crane motors, handling heavy loads during extended operation, are especially vulnerable to overheating. This can cause shutdowns, motor burnout, production delays, and safety hazards, making effective motor overheating protection essential for any crane fleet.

2. Main Causes of Motor Overheating

Common main reasons for crane motor overheating in high-temperature environments include:

Aging or clogged cooling systems.

Excessive loads or overloading.

High ambient temperatures preventing timely heat dissipation.

Poor lubrication increasing internal friction.

Existing insulation aging issues within the motor itself.

Especially for heavily loaded double-girder overhead cranes, these problems are more concentrated. Neglect can easily lead to continuous equipment damage.

3. 5 Practical Motor Overheating Protection Tactics

Implement these strategies for reliable crane operation:

Install Forced Ventilation: Add external fans for double-girder overhead crane motors to boost cooling.

Apply High-Temperature Lubricating Grease: Use specialized high-temperature lubricating grease to reduce friction.

Deploy Intelligent Temperature Control: Equip motors with intelligent temperature control systems for real-time monitoring – a core motor overheating protection measure.

Optimize Operating Schedules: Avoid heavy crane lifting during peak heat (12 PM-3 PM).

Enhance Summer Maintenance: Prioritize double-girder overhead crane motor inspections and verify intelligent temperature control functionality.

4.Conclusion: Prioritize Protection for Crane Safety

The double-girder overhead crane is fundamental to industrial material handling. Its reliability hinges on proactive motor overheating protection, especially during summer. Implementing targeted measures like ventilation upgrades, high-temperature lubricating grease, and intelligent temperature control allows businesses to maintain crane productivity and safety in demanding thermal environments. Diligent maintenance and load management are the true cornerstones of maximizing crane uptime and longevity.