What is the difference between a fixed crane and a rail-mounted crane?

Structure and installation method

Fixed cranes are usually fixed in a specific location, usually fixed to the dock foundation or ground foundation by anchor bolts and other means. For example, the fixed load-bearing variable-luffing crane GQ1 type has its bottom firmly fixed to the port ground and the overall structure is stable. After its installation position is determined, the working range is mainly the area that can be covered by the luffing and rotation of its boom, and this area is relatively fixed. Since it does not need to move, its structure is relatively simple, there is no walking mechanism for movement, the center of gravity is low, and the stability is good.

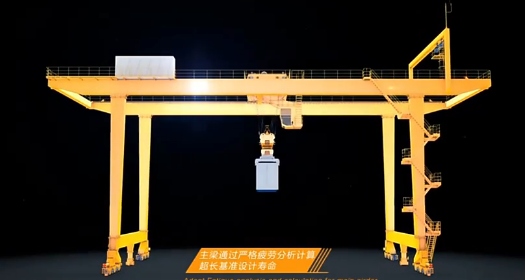

Rail cranes are installed on rails, such as rail-mounted container gantry cranes, which have special running wheels at the bottom, and the running wheels run along the laid rails. The laying of the rails depends on the layout of the port and the operation requirements, and can guide the crane to move on a certain route. The structure is relatively complex because it is necessary to consider the stability, guidance, and power transmission of running on the rails. In addition to the lifting and luffing mechanisms, there are also running mechanisms, including motors, reducers, wheels and other components to ensure that the crane can run smoothly along the rails.

Working range and flexibility

The working range of fixed cranes is limited, mainly depending on the length, height and slewing angle of the boom. For example, the fixed non-loaded variable-luffing crane GQ2 type can only operate within a certain radius and height range around its fixed position. However, it can carry out efficient loading and unloading operations within this fixed range, especially for some specific loading and unloading points or scenes that require frequent operations in a small range. It is less flexible and cannot be transferred to other operating areas as quickly as rail-mounted cranes. If the port needs to carry out loading and unloading operations at a distant location, fixed cranes cannot be used unless they are reinstalled or other auxiliary equipment is used to transfer the cargo. Rail-mounted cranes have a wide working range and can be moved along the track to different locations for loading and unloading operations. Taking the rail-mounted container gantry crane as an example, it can cover a long area in the port by moving on the track, such as moving along the track at the front of the terminal to operate ships docked at different locations or container yards in different areas of the terminal. It has high flexibility and can quickly adjust the operating position according to the port's operating plan and actual cargo distribution, effectively improving the efficiency of equipment use. It has obvious advantages, especially when dealing with cargo loading and unloading tasks distributed in a large area.

Application scenarios and operating efficiency

Fixed cranes are suitable for scenarios where cargo loading and unloading points are relatively fixed, cargo flow is large and concentrated in a small area. For example, in some small inland river terminals, the types of cargo to be loaded and unloaded and the berthing positions of ships are relatively fixed, and fixed cranes can efficiently complete loading and unloading tasks. For specific operations, the operating efficiency is high. If the cargo loading and unloading tasks within its working range are continuous and frequent, it can achieve efficient loading and unloading through rapid lifting and rotation movements. For example, in a coal loading and unloading terminal, a fixed crane can continuously unload coal from the ship to the conveyor belt on the shore, or load coal onto a truck in a fixed coal loading and unloading area, with high efficiency.

Rail cranes are widely used in container terminals and bulk cargo terminals in large ports. At container terminals, it can move along the track to the designated container ship position to load and unload containers, and can also transport containers back and forth between the terminal yard and the ship. At bulk cargo terminals, it can move to different bulk cargo loading and unloading points to handle the loading and unloading of bulk cargo such as ore and grain. Operating efficiency is affected by the track layout and the speed of crane movement. During the movement, the operating efficiency may be lower than that of fixed cranes in some cases due to speed restrictions or track crossings. However, when handling large-scale, dispersed cargo loading and unloading tasks, the overall operating efficiency is higher because it can quickly reach different operating locations and reduce cargo handling time.