As global manufacturing faces severe labor shortages and skill gaps, companies urgently seek automated, labor-light solutions. In this context, Electric Overhead Traveling Cranes—with their intuitive controls and minimal maintenance—have emerged as the prime choice for material handling upgrades, directly addressing core workforce challenges.

1. Labor Crisis: Efficiency Limits of Traditional Equipment

Factories typically rely on two systems:

Overhead Bridge Cranes: Require certified operators with lengthy training cycles and high labor costs;

Manual forklifts/hydraulic carts: Low efficiency, high injury risks, and employee turnover.

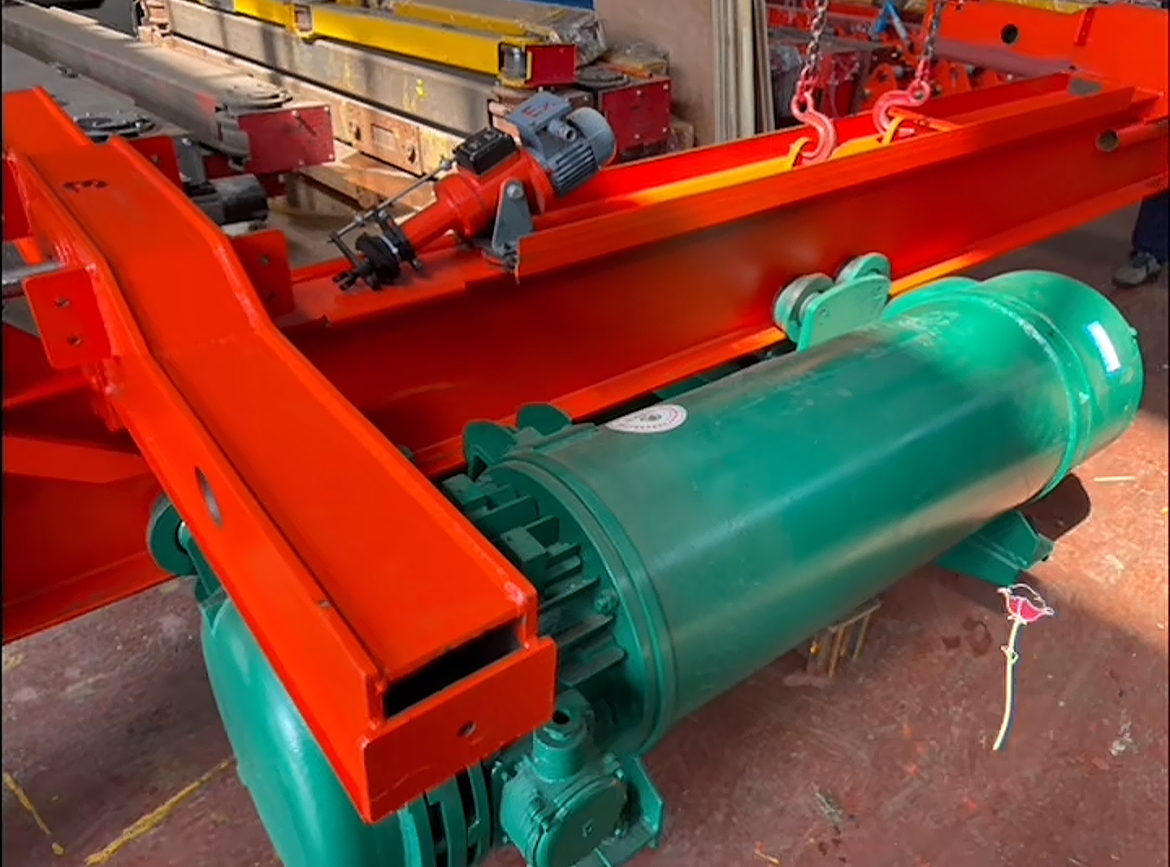

Electric Suspension Cranes enable "one-operator-multiple-cranes" workflows via wireless remote + anti-sway tech, drastically reducing skilled labor dependency.

2. Operation Revolution: 3 Designs Enabling "Zero-Learning-Curve"

Electric Overhead Traveling Cranes simplify interaction through:

Ergonomic Wireless Remote: Logical button layout with <0.1s response delay; Controls up to 8 cranes simultaneously.

Adaptive Frequency Drives: Smooth acceleration/deceleration prevents load swing (ideal for beginners).

Visual Diagnostics: Real-time error codes (e.g., E01: Motor Overheat) simplify troubleshooting.

Compared to traditional Overhead Bridge Cranes needing dedicated operators + signalers, efficiency increases by 40%.

3. Maintenance Showdown: Suspension Cranes Save $10k+/Year

| Maintenance Item | Electric Suspension Crane | Overhead Bridge Crane |

|---|---|---|

| Annual Service Cycles | 1 | 4 |

| Wear-Part Replacement | <$300 | >$1,200 |

| Certified Tech Required | No | Yes |

4. Case Study: Auto Parts Plant’s 35% Efficiency Leap

After installing 3 Electric Suspension Cranes at a Zhejiang EV component factory:

Material handling staff reduced from 12 → 3 (saving $75,000/year);

Crane-related downtime dropped 92%;

Product turnover speed increased 35%.

*"We delayed shipments due to Overhead Bridge Crane operator scheduling issues. Now, any worker operates cranes after 1-hour training."* – Production Director Mr. Wang

5. Suspension vs. Bridge Cranes: Selecting the Right Tool

| Scenario | Recommended Equipment | Key Reason |

|---|---|---|

| High-frequency light loads | Electric Overhead Traveling Crane | Production-line agility |

| Heavy fixed-position lifts | Overhead Bridge Crane | High-tonnage stability |

| Cross-facility transport | Electric Suspension Crane + tracks | Full-plant coverage |

Conclusion: Beating the "No Workers" Crisis with Smart Tech

As labor costs surge and skilled workers vanish, Electric Suspension Cranes offer sustainable material handling through foolproof operation and near-zero maintenance. Their modularity supports seamless scaling—from single workstations to plant-wide smart logistics—making them strategic investments against labor shortages.