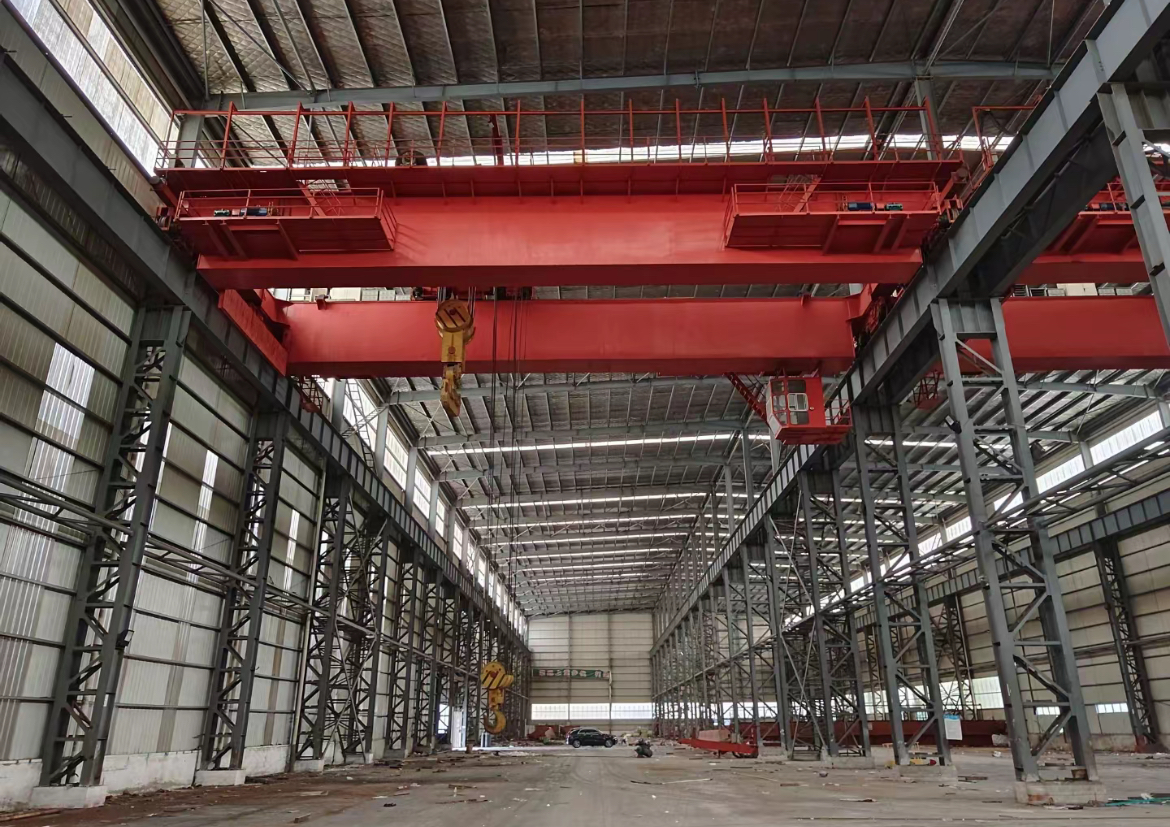

Protective measures for QD double-beam bridge cranes in high temperature environments

Introduction: Operational Challenges in Heat

Elevated temperatures pose significant risks to material handling systems. General bridge cranes, heavy-duty double-beam bridge cranes, and precision-engineered QD double-beam bridge cranes all experience accelerated wear and potential failures under thermal stress. Implementing tailored high-temperature protection protocols is essential for safety and longevity.

System-Specific Thermal Impacts

Structural Integrity Concerns

1. Standard overhead lifting systems exhibit beam expansion-contraction cycles causing alignment issues

2. Twin-girder configurations experience amplified stress at connection points

3. Precision-engineered QD-type double-girder units show vulnerability at complex joints

Electrical System Vulnerabilities

1. Motor insulation degradation accelerates in all configurations above 45°C.

2. Control logic stability decreases significantly in integrated PLC systems.

3. VFD lifespan reduces 30% per 10°C rise in precision hoisting mechanisms.

Hydraulic Performance Reduction

1. Oil viscosity breakdown reduces efficiency by 15-25% across systems.

2. Seal leakage rates double at >60°C ambient temperatures

3. Precision lifting functions require strict thermal management

Targeted Protection Protocols

Structural Protection Measures:

| Solution | General Application | Heavy-Duty Focus | Precision Systems |

|---|---|---|---|

| Ceramic thermal coatings | All exposed surfaces | Beam connections | Trolley rail interfaces |

| Aluminum reflective shields | Optional | Critical for main beams | Required + ultrasonic testing |

| Composite insulation | Operator walkways | Full walkway coverage | Cabin sun barriers |

Electrical System Preservation

Standard systems: Mandatory motor cooling fans; NEMA 12 cabinets with forced ventilation.

Heavy-capacity models: Temperature-triggered cabinet ventilation (40°C threshold); fiberglass cable trays.

Precision lifting units: Dedicated cabinet air-conditioning (≤35°C); encoder thermal shrouds with adequate lubrication.

Hydraulic System Maintenance

All configurations: Annual oil analysis; synthetic high-temp fluids (ISO VG 46+).

Critical systems: Monthly pressure decay tests; piston rod thermal stress monitoring.

QD-specific: Biweekly seal inspections; graphite-based high-temp lubricants.

Operator Safety Enhancements

Climate-controlled cabins (25±1°C) for all double-beam bridge crane operations.

Solar-adaptive window films for QD double-beam bridge crane cabs.

Shift rotation protocols avoiding 11:00-15:00 peak heat periods.

Predictive Monitoring Systems

Wireless temperature sensors on all bridge crane power transmission units.

Automated shutdown sequences for double-beam bridge crane motors exceeding Class B limits.

Quarterly thermographic thermal stress mapping for QD double-beam bridge crane support structure.

Conclusion

Effective high-temperature risk mitigation requires a tiered protection strategy aligned with crane specifications. Foundational safeguards (structural coatings, electrical cooling) suffice for standard bridge cranes. Enhanced monitoring protocols become essential for double-beam configurations due to their structural complexity and higher loading. The sophisticated QD double-beam bridge crane demands the most rigorous approach: precision temperature control for electrical/hydraulic systems complemented by proactive thermal stress analysis.

Implementing these tailored measures—whether for basic bridge cranes, robust double-beam models, or advanced QD double-beam bridge cranes—delivers critical operational benefits:

30-40% extended service life.

50% reduction in heat-related downtime.

Elimination of temperature-induced safety incidents.

This crane-specific protection framework represents a vital investment in both operational resilience and personnel safety under extreme thermal conditions.