Double-Beam Bridge Cranes and Hoisting Systems: Innovations for Industrial Resilience

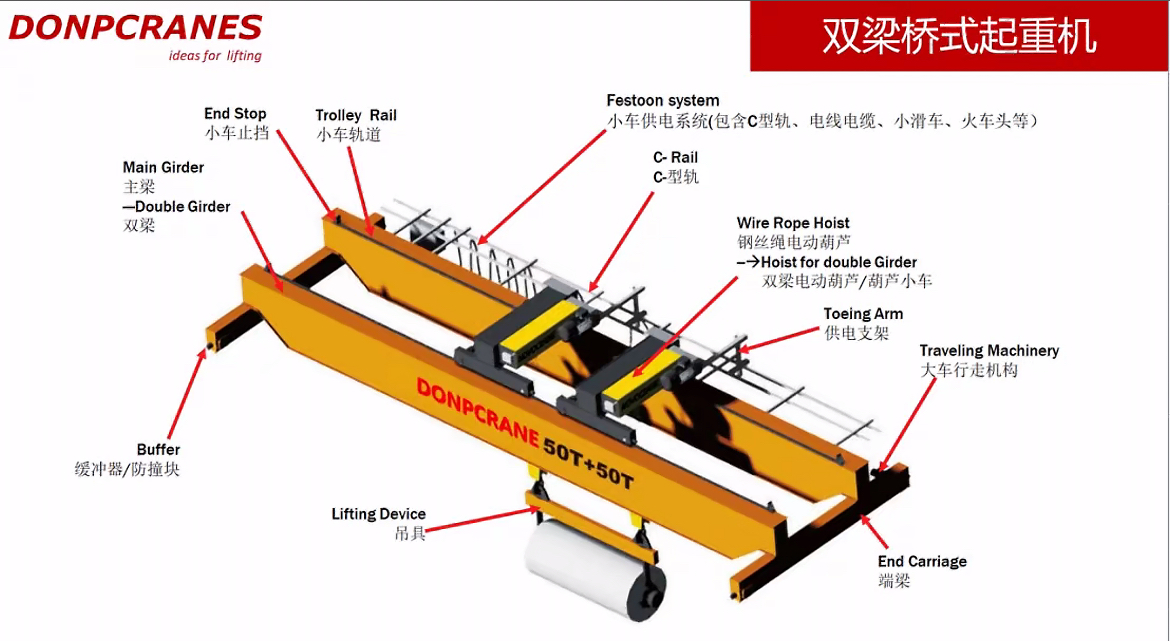

Double-beam bridge cranes and their hoisting systems form the backbone of industrial material handling. Structural and operational advancements in these systems now prioritize synergistic optimization between crane frameworks and hoisting systems to address safety, fatigue, and automation challenges.

1. Critical Challenges in Double-Beam Bridge Crane and Hoisting System Design

1.1 Load Dynamics Across Systems

Uneven dynamic loads in double-beam bridge cranes amplify stresses on hoisting systems, particularly during acceleration. Main beam deflection exceeding L/700 standards disrupts hoisting system alignment, accelerating wire rope wear.

1.2 Hoisting System-Specific Fatigue Mechanisms

Hoisting systems endure 30% higher cyclic stresses than crane structures due to abrupt load shifts. Metallurgical plant data show drum weld cracks propagate 40% faster in hoisting systems under 24/7 duty cycles.

1.3 Environmental Impacts on Dual Systems

While double-beam bridge cranes face thermal warping, hoisting systems in coastal sites suffer salt-induced pulley corrosion – a leading cause of premature brake failures.

2. Integrated Optimization Strategies

2.1 Structural-Hoisting System Co-Design

Hybrid box-truss beams reduce hoisting system sway by 18% through torsional stiffness improvements. FEA-optimized cross-sections lower dynamic loads on hoisting systems by 22% in Q690 steel configurations.

2.2 Hoisting System-Specific Upgrades

Dual-Drive Synchronization: CAN bus integration in hoisting systems cuts motor torque variance to <5%

Smart Drum Configurations: Waveform-optimized grooving extends hoisting system rope life by 1,200 cycles

2.3 Material Synergies

Q690 steel adoption in double-beam bridge cranes permits 20% lighter hoisting system trolleys without capacity loss.

3. Intelligent Monitoring Advancements

3.1 Hoisting System-Centric Predictive Analytics

FBG sensors on hoisting system drums detect 50 μm deformation shifts – 300% earlier than vibration monitoring.

3.2 Dual-System Failure Prevention

AI vision now correlates double-beam bridge crane deflection patterns with hoisting system overload risks, achieving 98% failure prediction accuracy.

4. Case Study: Systemic Retrofit

A steel mill upgraded both double-beam bridge crane beams and hoisting systems simultaneously:

Hoisting system variable-frequency drives reduced peak motor loads by 35%

Beam reinforcement cut hoisting system maintenance costs by $8,200/year