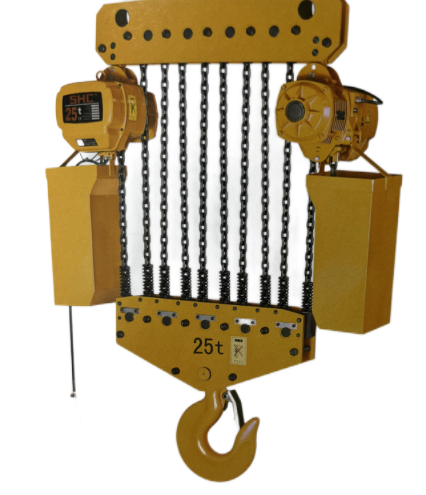

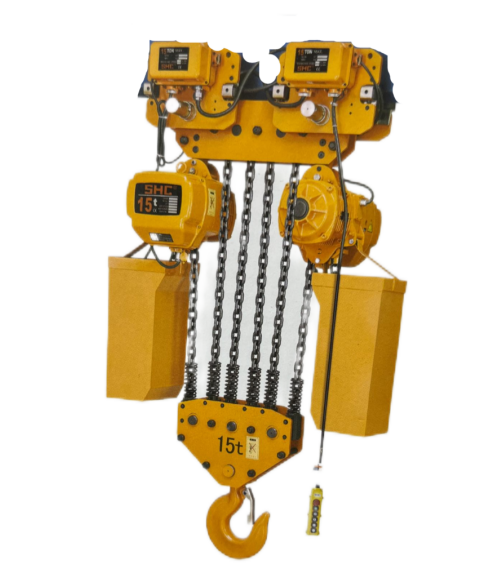

1. Design Philosophy: Modular Innovation vs Conventional Frameworks

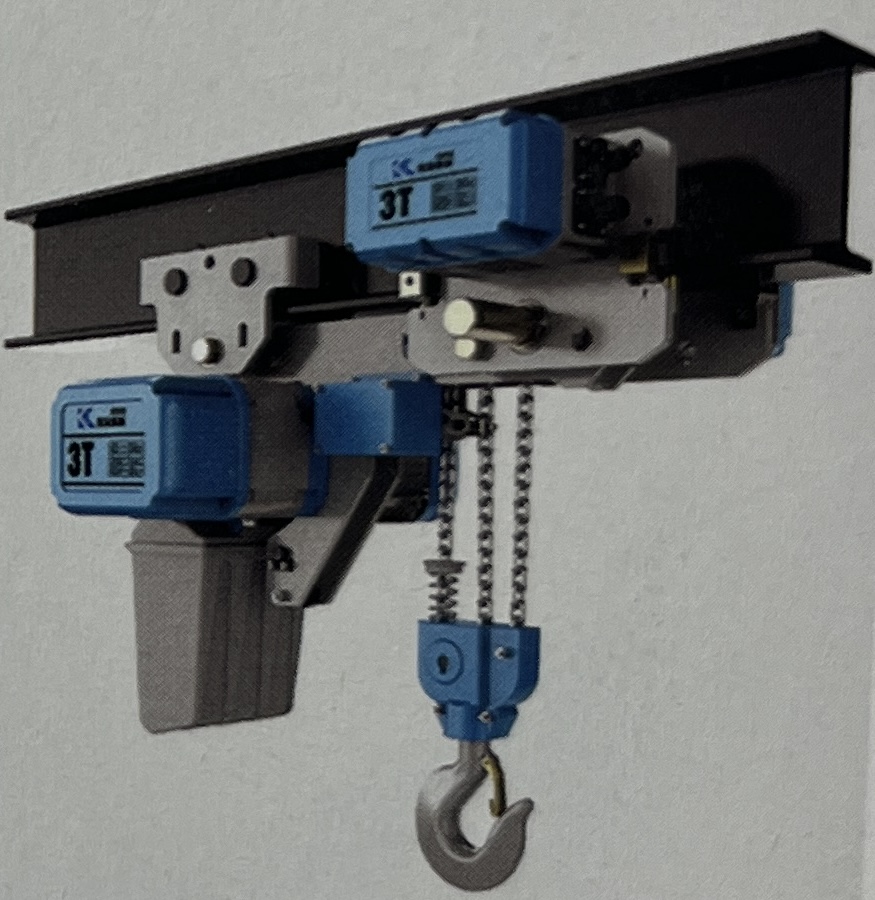

1.1 European Hoists: Modular Engineering Excellence

3D Parametric Design: Achieves 85% modularization (e.g., Demag ED Series: 17 modules → 120 configurations).

Space Efficiency: 30% lighter than traditional counterparts (10-ton model: 2.1t vs 3.2t).

Operational Impact:

70% faster height adjustments

45% fewer spare parts required

15% production boost in steel plants through layout optimization

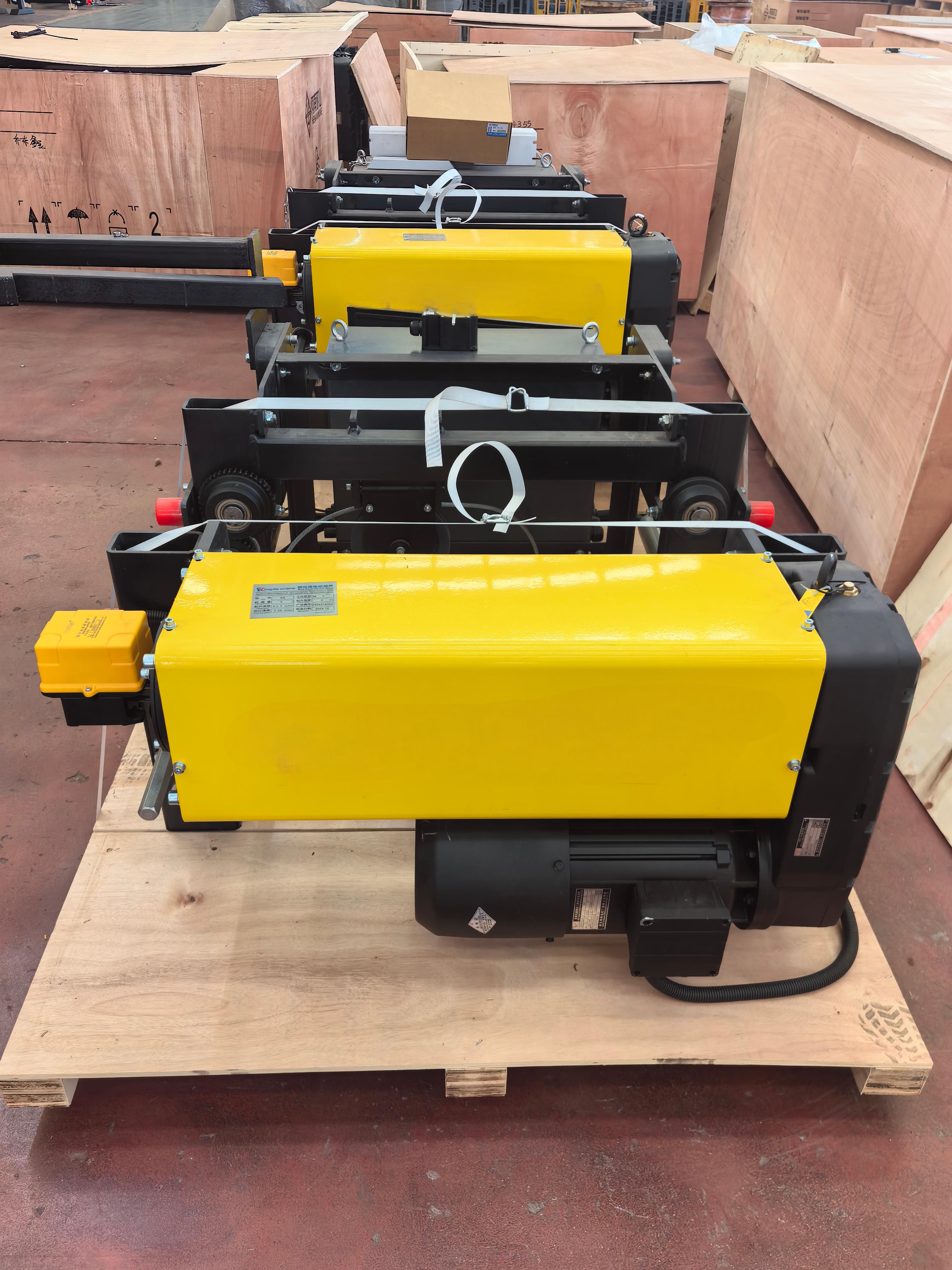

1.2 Traditional Hoists: Legacy Structural Limitations

1960s Soviet-Era Framework: Linear drum-reducer-motor layout increases length by 40%.

Space Constraints: Occupies 2.3㎡ more floor space per unit, reducing factory layout flexibility.

2. Component Technology: Bridging the Performance Gap

2.1 Lifting Mechanism Breakthroughs

Planetary Gear Reducers:

96% efficiency vs 83% in worm gears

HRC60-62 hardened gears (50,000+ hours lifespan)

Braking Systems:

Disc brakes: <0.1s response (65% shorter emergency stops)

2.2 Precision Movement Systems

European Models (STAHL SDB Series):

±1mm positioning accuracy

<2% speed fluctuation via VFD + conical motors

Traditional Systems:

15% speed variation causes 0.5-1mm positioning errors

2.3 Wire Rope Advancements

8×26WS Anti-Rotation Ropes (CASAR):

18% higher breaking strength

3-5x lifespan vs 6×37 conventional ropes

12-18 months service vs quarterly replacements

3. Material Science & Manufacturing Innovations

3.1 Lightweight Engineering

EN-GJS-600 Ductile Iron:

600MPa tensile strength (vs 250MPa in gray iron)

25% weight reduction

Aerospace-Grade Components:

7075 aluminum drums: 40% lighter, 32% lower inertia

3.2 Advanced Surface Treatments

QPQ Salt Bath Coating:

HV1100 hardness (8x more wear-resistant than galvanizing)

0.02mm gear wear after 80,000 cycles (vs 0.15mm in traditional units)

4. Smart Features & Safety Enhancements

4.1 IoT-Enabled Control Systems

CAN Bus Integration: PLC-compatible with ±0.5% load monitoring

Predictive Maintenance: 72-hour fault预警 (Schneider案例)

50ms Overload Response: 20x faster than mechanical systems

4.2 Fail-Safe Mechanisms

Dual Braking (EN14492-2 Compliant): Main + safety brakes

PTC Thermal Sensors: ±1℃ accuracy prevents motor burnout

5. Total Cost of Ownership Analysis

| Metric | European Hoists | Traditional Hoists |

|---|---|---|

| Initial Cost | 1.5–2x Higher | Baseline |

| Annual Energy Use | 12,000 kWh | 18,000 kWh |

| 5-Year Maintenance | 15% of Cost | 35% of Cost |

| Downtime/Year | <20 Hours | >80 Hours |

| 5-Year Residual Value | 60% | 30% |

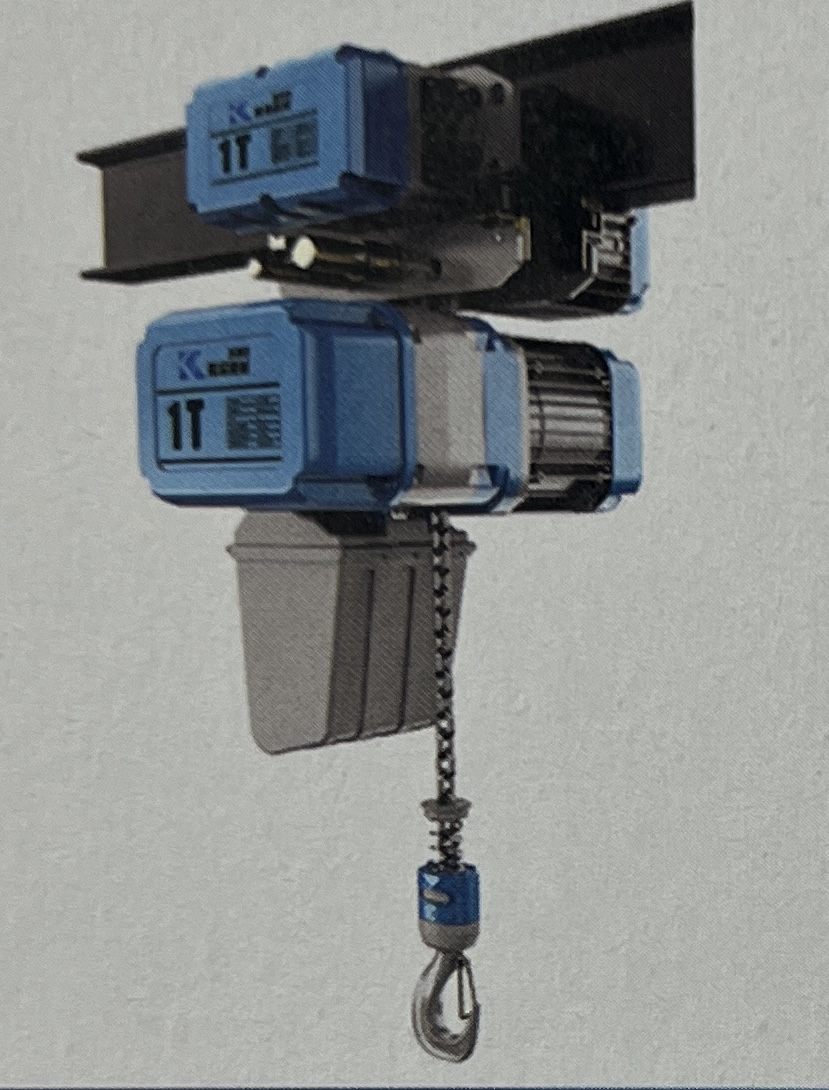

6. Application-Specific Advantages

European Hoist Dominance:

Clean Rooms: IP55 rating, <65dB noise

Precision Manufacturing: ±1mm repeatability

High-Intensity Operations: 300 starts/hour @ 100% ED

Traditional Hoist Niches:

Short-Term Projects: <2-year installations

Low-Usage Scenarios: <500 annual hours

Budget-Critical Operations

7. Market Trends & Future Outlook

4.8% CAGR Growth: Smart hoists to claim 35% market share by 2025

EU Machinery Regulation 2023/1230: Mandates predictive maintenance integration

Next-Gen Innovations: Digital twins, carbon fiber components

Conclusion

European electric hoists deliver superior ROI through energy efficiency, precision engineering, and smart manufacturing compatibility. While traditional models retain niche applications, Industry 4.0 demands are

accelerating adoption of modular, IoT-ready hoists. Facility managers should prioritize lifecycle cost analysis and future-proofing when upgrading material handling systems.