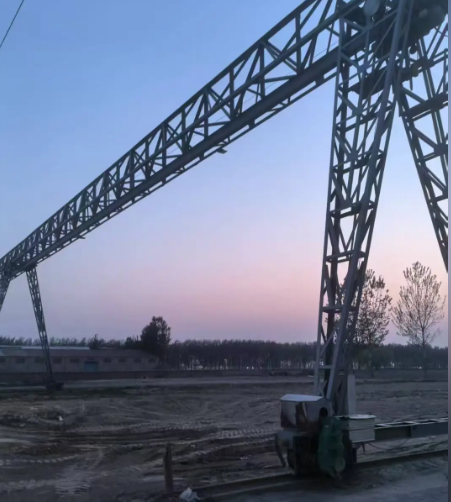

Truss Gantry Crane: Load Capacity and Customizable Engineering Solutions

In the realm of modern material handling, the Truss Gantry Crane stands out for its distinctive lattice-frame design and versatile applications. This specific type of Gantry Crane is engineered to offer a superior strength-to-weight ratio. Understanding the capabilities of a Truss Gantry Crane, particularly its load capacity and potential for customization, is crucial for selecting the right equipment. Furthermore, the Structural Integrity of the entire system is the foundational element that guarantees safe and reliable operation.

Load Capacity Analysis

The load-bearing capacity of the Truss Gantry Crane is a key parameter. It is not a fixed value but varies based on design and manufacturing specifications:

Wide Range: The load capacity typically ranges from a few tons to several tens of tons. Common specifications include 1, 2, 5, 10, and 20 tons, with large custom models capable of handling 50 tons or more.

Determining Factors: The capacity is primarily determined by the main beam structure, leg strength, material quality, and the specifications of the hoisting mechanism.

Application Matching: When selecting a Gantry Crane, users must determine the load rating based on the maximum lifting weight in daily operations, ensuring a sufficient safety margin for secure use.

Customization and Adjustment Flexibility

A significant advantage of the Truss Gantry Crane is its high degree of modularity and customizability, allowing it to adapt to various site and operational needs.

Dimensional Customization:

Span: The span of the main beam can be customized to fit the width of the available space.

Lifting Height: The lifting range can be adjusted according to the height of the workspace.

Structural Configuration: Options include fixed or mobile types, and single or double girder structures, tailoring the Gantry Crane to specific tasks.

Functional Enhancements: Additional features such as different travel drives (manual or electric), frequency control systems, or safety devices (like limit switches and anti-collision systems) can be added to meet advanced automation and safety requirements.

The Core Consideration: Structural Integrity

The realization of load capacity and the feasibility of custom solutions are fundamentally guaranteed by the equipment's Structural Integrity:

Foundation of Safety: Structural Integrity is the key indicator of the crane's ability to resist deformation and failure under load, directly impacting the safety of both personnel and equipment.

Design and Materials: The use of high-strength steel and a scientific truss design ensures Structural Integrity while minimizing the crane's own weight, achieving an optimal balance.

Prerequisite for Customization: Any custom adjustments, especially those involving increases in load capacity, must be based on recalculated and potentially reinforced Structural Integrity to ensure overall stability and reliability.

Summary

The Truss Gantry Crane is a powerful and flexible lifting solution. When selecting a model, users should first define their load capacity requirements, then consult with professional manufacturers to discuss customization options for dimensions and functions. Throughout this process, the product's Structural Integrity must be prioritized as the core standard for assessing its safety and durability.