Building the Safety Line: Ensuring the Safe Use of the Three Key Crane Components

In industrial settings, the reliable function of heavy equipment is critical. The safe operation of a crane depends entirely on the integrity of its core parts, with the crane hook, the crane wire rope, and the crane brake forming a critical safety triad. The failure of any one of these components can lead to severe accidents. Therefore, rigorous protocols for the crane hook, the crane wire rope, and the crane brake are non-negotiable for all personnel.

The Crane Hook: The Ultimate Load-Bearing Point

As the final link to the load, the crane hook must be in perfect condition. The integrity of every crane hook is the first gateway to safety:

Pre-Use Visual Inspection: A thorough visual check of the crane hook must be conducted before every shift. Inspect for surface cracks, wear, or deformation, paying close attention to the crane hook's bend and throat. The latch mechanism on the crane hook, if present, must function correctly.

Zero Tolerance for Damage: Any signs of permanent deformation, twisting, or cracking on a crane hook mandate its immediate removal from service. Never attempt to repair a damaged crane hook by welding or bending, as this compromises its metallurgical integrity.

Mandatory Safety Latch: A functional safety latch is essential for a standard crane hook. This device prevents slings or the crane wire rope from accidentally disengaging from the crane hook, a primary cause of load drops.

The Crane Wire Rope: The Flexible Lifeline

The crane wire rope transmits the lifting force, and its condition is a primary indicator of overall crane safety. Continuous monitoring of the crane wire rope is essential:

Detailed Examination for Defects: Regularly inspect the entire length of the crane wire rope. Look for broken wires, kinks, crushing, corrosion, or significant reduction in diameter. Critical inspection points include sections in contact with drums, sheaves, and end attachments.

Adherence to Discard Standards: Strictly follow the manufacturer's and regulatory standards for retiring a crane wire rope. Criteria are often based on the number of visible broken wires in one rope lay, outer wire wear, and signs of core damage. Do not exceed these limits.

Proper Handling and Care: Ensure the crane wire rope spools correctly onto the drum to prevent pinching and wear. Avoid shock loads by operating controls smoothly. Implementing a regular lubrication schedule for the crane wire rope significantly reduces internal friction and external corrosion.

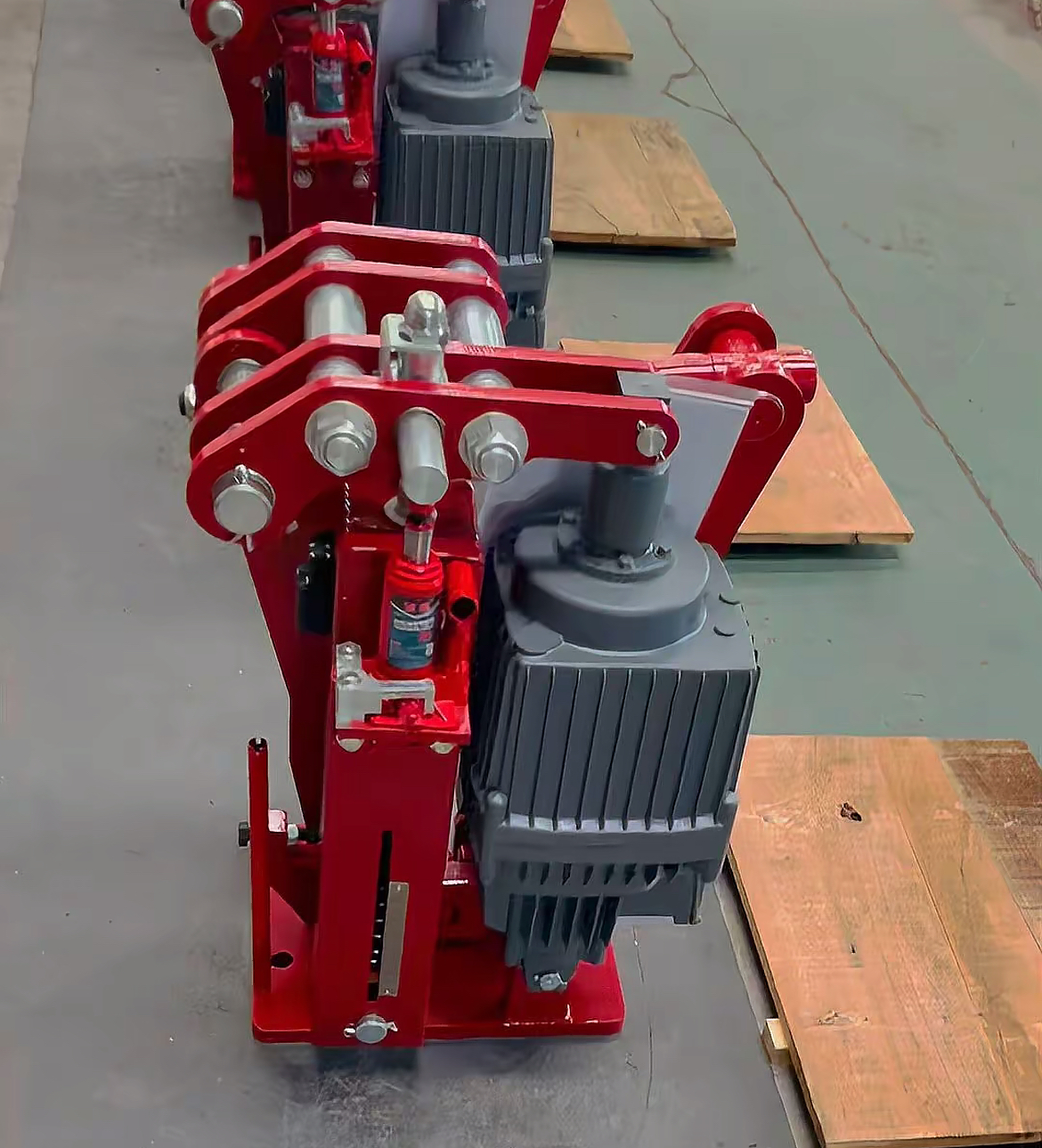

The Crane Brake: The Guarantee of Control

The crane brake is the fundamental safety device that controls and holds loads. The reliability of the crane brake is paramount for preventing unintended movement:

Functional Testing is Mandatory: Test the crane brake daily under both no-load and light-load conditions. Verify that it engages positively, holds the load without slipping, and releases smoothly. Any delay, unusual noise, or insufficient holding power requires immediate attention.

Monitor and Adjust for Wear: Friction components in the crane brake wear down over time. Regularly check the clearance and adjust the crane brake as specified by the manufacturer. Replace worn parts in the crane brake promptly to maintain the designed braking torque.

Maintain a Clean Operating Environment: Keep the crane brake assembly clean and free from contaminants like oil, grease, and dust, which can cause slippage. For hydraulically operated systems, monitor fluid levels and condition to ensure the crane brake functions as intended.

Conclusion

The crane hook, crane wire rope, and crane brake are the three pillars of crane safety. Their roles are distinct yet interdependent. A robust crane hook provides a secure attachment, a sound crane wire rope delivers the lifting force, and a dependable crane brake ensures precise control. A comprehensive safety culture, built on disciplined daily checks of the crane hook, crane wire rope, and crane brake, is the only way to ensure crane operations remain safe and productive.