Power in Precision: Distinguishing the Electric Winch, Electric Hoist, and Key Component Wire Rope

In the realm of industrial material handling, the electric winch and the electric hoist are two pivotal pieces of equipment. While both utilize wire rope as their primary load-bearing component, their design philosophies and application scenarios are fundamentally distinct. The choice between an electric winch and an electric hoist hinges on whether your core need is horizontal pulling or vertical lifting. Understanding the difference between an electric winch and an electric hoist is crucial for safety and efficiency.

Core Function: The Divide Between Pulling and Lifting

The most fundamental difference is that the core function of an electric winch is horizontal pulling, while the core function of an electric hoist is vertical lifting:

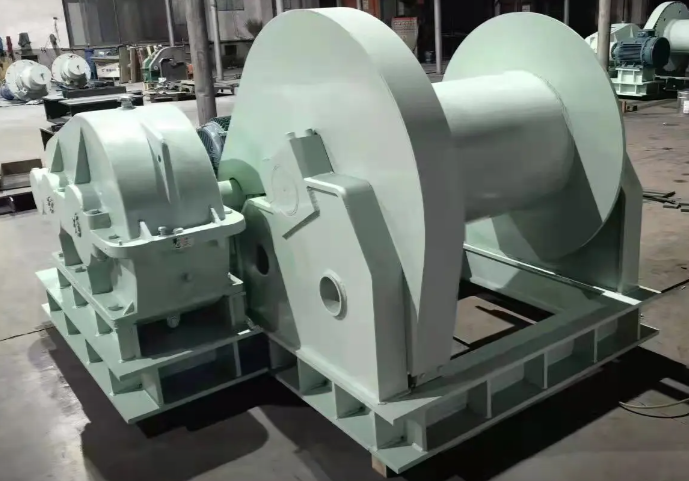

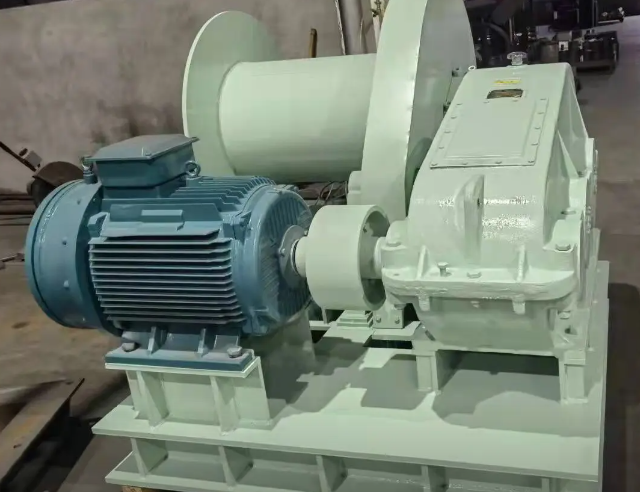

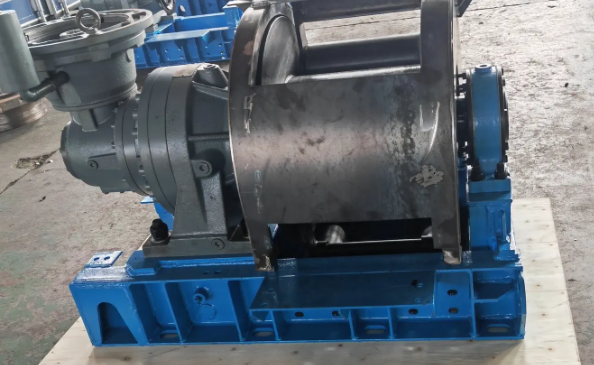

The primary mission of an electric winch is to generate immense pulling force for horizontal or inclined dragging. An electric winch operates by powerfully spooling wire rope onto its drum to pull loads across a surface. Common applications for an electric winch include vehicle recovery, boat launching, and tensioning cables. The performance of a winch is typically defined by its line pull capacity.

An electric hoist is a device born for "lifting." It is usually mounted underneath an I-beam track, capable of vertical hoisting and horizontal movement along the track. Its design focuses on safely and precisely lifting and lowering loads vertically and transferring them within a limited area. It is widely used in factory workshops and warehouses on assembly lines for hoisting components, machinery, and equipment.

Structure and Application: Portable vs. Fixed Installation

Differences in structure directly determine their application methods:

An electric winch is often a more standalone unit. It can be mounted on a vehicle, the ground, or a platform. The wire rope on a winch is deployed and retrieved as needed for pulling tasks.

An electric hoist, in contrast, is an integrated lifting system. It must be part of a supporting structure. The wire rope or chain on an electric hoist moves vertically, with the load suspended directly from the hook.

Wire Rope: The Common Link with Different Demands

The wire rope is the vital, common component connecting the electric winch and the electric hoist, yet its operational demands differ:

In an electric winch, the wire rope is subjected to harsh conditions, often spooling in multiple layers and abrading against the ground. The wire rope for a winch must be extremely durable and resistant to crushing.

In an electric hoist, the wire rope is typically spooled in a single layer, prioritizing smooth operation and tensile strength under a direct vertical load. The integrity of the wire rope is paramount for the safety of any hoist.

Conclusion: Making the Correct Choice

Your primary task objective dictates the right tool:

Choose an electric winch for horizontal dragging, linear pulling, and recovery operations.

Select an electric hoist for vertical lifting, precise lowering, and overhead material handling.

In summary, the electric winch is your powerful "pulling master," while the electric hoist is your agile "lifting master." Properly understanding the roles of the electric winch and the electric hoist, along with selecting the appropriate wire rope for each, ensures that these powerful tools perform safely and effectively in their respective specialties.