Analysis of the Driving Forms for Electric Top-Running Bridge Cranes and Their Trolley Travelling Mechanisms

In the realm of modern industrial logistics and heavy manufacturing, the overhead crane stands as a pivotal piece of equipment for the handling of heavy loads. A particularly prevalent variant in many industrial settings is the electric top-running bridge crane, recognized for its efficient utilization of workspace and structural robustness. The fundamental operation of any overhead crane is dependent on its capability for precise longitudinal and transverse load movement, a primary function facilitated by the trolley travelling mechanism. This article provides a detailed examination of the electric overhead travelling crane, with a dedicated focus on the common driving configurations utilized in its trolley travelling mechanism.

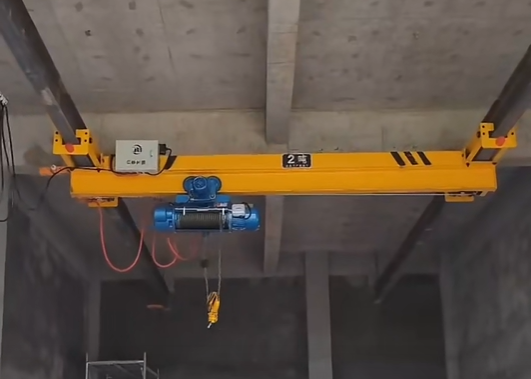

The standard configuration of an electric overhead travelling crane encompasses a bridge girder supported by end trucks, a hoisting unit, and the crucial trolley travelling mechanism. The defining "top-running" feature, where the crane rails are mounted on top of the runway beams, offers a distinct advantage in standard workshop clearances. The reliable and smooth operation expected from a modern overhead crane is heavily contingent on the performance of its trolley travelling mechanism. This subsystem is solely responsible for the precise transverse positioning of the load across the width of the bridge, making its design and drive form critically important for the overall efficiency of the overhead crane.

The engineering of the trolley travelling mechanism has a direct and profound impact on the crane's operational precision, stability, and long-term service life. The industry has standardized several reliable driving forms for this essential component of the overhead crane:

The "Three-in-One" Drive System: This represents the current industry standard and the most widespread solution for modern electric overhead travelling cranes. It ingeniously integrates the motor, the brake, and the reducer into a single, compact, and modular unit. This advanced design offers significant benefits for the trolley travelling mechanism, including reduced weight, high transmission efficiency, and simplified maintenance, thereby enhancing the overall reliability and performance of the overhead crane.

Horizontal Reducer Drive Form: This is a more traditional transmission method. The motor is connected to a horizontally mounted reducer via a coupling. The output shaft of the reducer then transmits power to the trolley's active wheels through another set of couplings and a transmission shaft system. This form has a robust structure and strong load-bearing capacity, but the overall structure is relatively bulky, heavy, and occupies more space. In the design of modern new electric overhead travelling cranes, it is gradually being replaced by the "three-in-one" form.

The Vertical Reducer Drive Form: This specific configuration utilizes a motor coupled with a vertically oriented gear reducer. This particular spatial arrangement is beneficial for saving horizontal space, resulting in a notably compact trolley travelling mechanism design. This makes it a suitable technical solution for various overhead crane applications where specific spatial constraints on the trolley platform are a primary design consideration.

Conclusion

In conclusion, the operational efficacy, precision, and reliability of the electric overhead travelling crane are inextricably linked to the advanced engineering and performance of its trolley travelling mechanism. The continuous evolution of these drive forms, marked by the transition from traditional reducer-based systems to sophisticated, integrated "three-in-one" units, clearly underscores the industry's persistent drive towards achieving greater operational efficiency, compactness, and maintenance simplicity for the contemporary overhead crane, solidifying its indispensable role in modern industrial infrastructure.